Traditional liquor brewing technology

-

Last Update: 2020-06-20

-

Source: Internet

-

Author: User

Search more information of high quality chemicals, good prices and reliable suppliers, visit

www.echemi.com

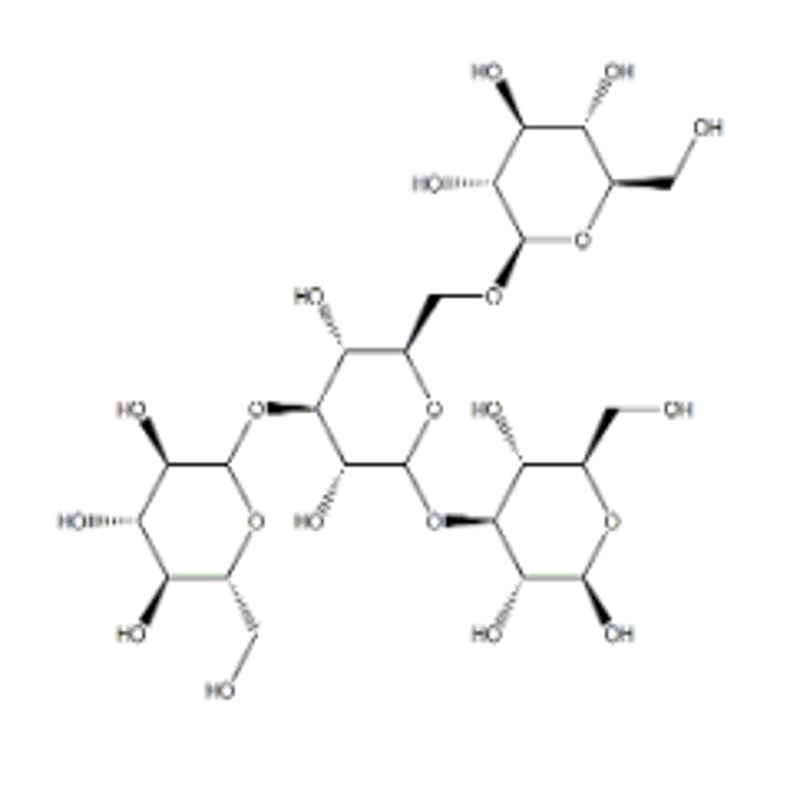

Liquor, commonly known as shochu, is a high concentration of alcoholic beverages, generally 50 to 65 degreesAccording to the different saccharification, fermentation bacteria and brewing process used, it can be divided into three categories: large qurwhich wine, small qualcomm, bran wine, of which bran wine can be divided into solid fermentation wine and liquid fermented wineThe following small compilation of traditional liquor brewing technology for a specific introductionraw material formula can be made with starch and sugar, but different raw materials produce a variety of white wine flavorGrain sorghum, corn, barley, sweet potato, cassava, sugary raw materials sugar cane and beet slag, waste molasses, etccan be made wineIn addition, sorghum, rice bran, bran, rice water, starch slag, sweet potato chips, beet head and tail, etc., can be used as substitute raw materialsWild plants, such as acorns, jugpotatoes, pears, golden cherry blossoms, etc., can also be used as substitute raw materialsThe traditional liquor brewing process in China is a solid fermentation method, in the fermentation need stoic to add some auxiliary materials, in order to adjust the concentration of starch, to maintain the softness of the wine, to maintain the slurry waterCommonly used accessories are rice shell, grain bran, corn core, sorghum shell, peanut skin and so onwine, wine, in addition to raw materials and accessories, but also need to have wine musicWhen producing liquor from starch raw materials, starch needs to undergo hydrolysis of a variety of amylase to produce sugarthates that can be fermented in order to be used by yeast, a process called glycation, and the glycosisis used is called cric (or wine, glycosis)Qu is a starch-based raw material to do the medium, culture a variety of mold, accumulation of a large number of amylase, is a crude enzyme preparationAt present, commonly used glycation is large (production of famous wine, high-quality wine), small music (production of small music wine) and bran (production of bran liquor)The most widely used in production is branthe process of traditional liquor brewing technology:crushing, ingredients, finishing and mixing, steaming paste, cold dispersal, adding music, water accumulation, fermentation into the pool, steaming wine out of the pool 8 processes crushed: ancient stone mill or (donkey grinding) to crush the sorghum into four or six petals, into a plum-shaped shape, and then with electric grinding into a standard sieve of raw materials ingredients: the crushed raw material surface and steamed accessories (rice shell) according to the ratio of 100:25-30 artificial mixing evenly In summer, it is generally 25% of the accessories and in winter it is 30% moisturizing material, mixing material: will be mixed with the noodles, according to the raw grain amount of 40-50% of the water for the finishing material, water temperature for room temperature, mixing evenly, stacking about 1 hour, so that the grain fully absorbs water, is conducive to paste, water moisture moisture and not sticky, experienced winemaker with a pinch can feel steaming paste: the noodles will be cooked on the pot for steaming, cooking before the pasta will be mixed again, and then with a wood pickaxe and spinach will be layer by layer into the pan, waiting for the steam round after steaming paste for about 1 hour, so that the noodles cooked without sticking, inside no heart, by the experienced winemaker hand-to-hand to feel the degree of cooking cold scattered: the steamed noodles with a wooden shovel out of the pot to put down the ground with a wooden pickaxe thin, uniform, natural cold dispersal, half-way mix several cold scattered, depending on the temperature reached summer 20-22 degrees C is appropriate, winter for 16-18 degrees C is appropriate , add music, add water accumulation: will be scattered good noodles according to the proportion of raw materials about 25%, add about 50% of the water, water for room temperature, with wood pickaxe for mixing, make it even, with the palm of the palm of the noodles from the finger sewing squeeze 1-2 drip is appropriate, and then the accumulation time is not less than 1-2 hours into the cylinder fermentation: the accumulation of good wine with bamboo into the cylinder manually, the top cover of the stone cover for fermentation, the cylinder is generally buried in the ground, the cylinder mouth and the ground flush, the spacing of the cylinder is 10-20cm The starch content of the wine is between 9-12%, the water content is between 55 and 57%, the acidity is between 0.8-1.1mol/g, and the sugar content is 0.5-0.6 The fermentation cycle is typically 21 days between Be' fermentation to grasp the changes in wine, generally should follow the "front slowly rise, medium,high, slow down" principle That is, after entering the cylinder, the temperature gradually rises, the fermentation medium, the temperature should be stable for a period, and then to the late fermentation, the fermentation temperature slowly decreased before the slow rise: the general cylinder to 6-7 days of temperature rose to 25-27 degrees C, sweet wine, indicating normal fermentation : from the 8th to 11th day of the cylinder, the temperature dropped to 32-34 degrees Celsius for four consecutive days after the slow fall: from 12 days to 21 days, the temperature gradually decreased, every day to drop 0.5 degrees C as appropriate, out of the cylinder when the temperature of the wine drop to 26-28 degrees C, fermented good wine should have a not hard, non-stick feeling, color is fuchsia out of the cylinder steaming wine: fermentation to 21 days of wine with bamboo to the side of the pot for distillation, loading should be in accordance with the "steady, accurate, fine, uniform, thin, flat" principle of operation, loading steam should be in accordance with the "two small one" principle of operation, flow Wine steam should be in accordance with the "chinese wine flow wine, atmospheric tailing" principle of operation, wine should be in accordance with the degree of size of the wine to judge the head, the original wine and the tail, see the flower wine is based on the experience of the wine master to judge, the wine generally received 0 degrees Wine head, original wine and tail are graded cylinder storage, generally stored for more than 6 months wine body ripening In addition, sugar is produced by yeast-secreted cider enzymes, converted into alcohol and other substances, known as alcohol fermentation, this process is used in the fermentation agent called the wine The wine mother is based on sugary substances as a medium, the yeast after a considerable pure expansion culture, the resulting yeast proliferation culture Production with more large cylinder wine mother the wine mother is based on sugary substances as a medium the production method of traditional liquor: 1 Raw material crushing The purpose of raw material crushing is to make it easy to cook and make full use of starch According to the characteristics of raw materials, the fineness of crushing requirements are also different, potato dried, corn and other raw materials, through 20-hole sieve accounted for more than 60% 2 Combine new ingredients, wine waste, accessories and water to lay the foundation for glycation and fermentation Ingredients should be based on the size of the barrel, cellar, raw material starch, temperature, production process and fermentation time and other specific circumstances, the specific performance of the ingredients, depending on the concentration of starch into the pool, the acidity of the ingredients and the degree of relaxation is appropriate, generally to starch concentration of 14 to 16%, acidity 0.6 to 0.8, moisture 48 to 50% is appropriate above is about the traditional liquor brewing technology and other knowledge introduction Read more and read the following related article: "thick-scented liquor" is not "composite ingredients" the type of common precipitation of liquor, the cause the main points of brewing liquor song manufacturing

This article is an English version of an article which is originally in the Chinese language on echemi.com and is provided for information purposes only.

This website makes no representation or warranty of any kind, either expressed or implied, as to the accuracy, completeness ownership or reliability of

the article or any translations thereof. If you have any concerns or complaints relating to the article, please send an email, providing a detailed

description of the concern or complaint, to

service@echemi.com. A staff member will contact you within 5 working days. Once verified, infringing content

will be removed immediately.