-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Honeywell announced that it will form a joint venture with Avangard innovation to build an advanced recycling facility in Texas

.

The plant will use Honeywell's new technology, UpCycle

.

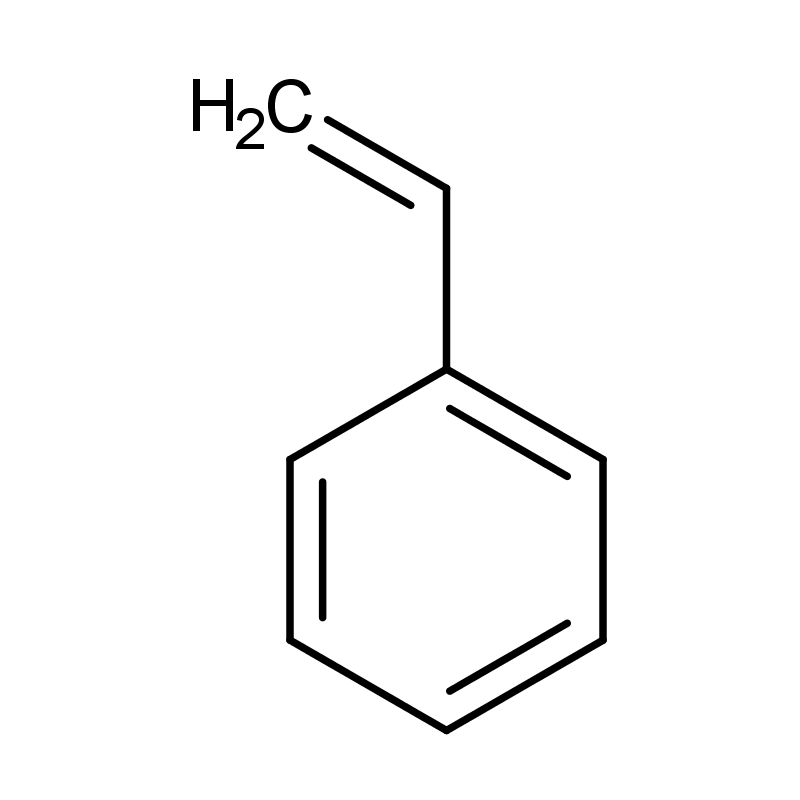

The UpCycle process technology utilizes industry-leading molecular transformation, pyrolysis and contaminant management technologies that significantly broaden the range of recyclable plastics to include previously unrecyclable waste plastics such as colored, flexible, multi-layer packaging or polystyrene

.

When combined with other chemical and mechanical recycling processes and improvements in collection and sorting processes, UpCycle technology is expected to increase the proportion of plastic waste that is recycled globally to 90%

.

UpCycle is able to reduce the consumption of fossil raw materials in the production of plastics, and its goal is to achieve a circular economy for plastics

.

According to Honeywell, recycled plastic produced using the UpCycle process technology can reduce carbon dioxide equivalent (CO2e) emissions by 57% compared to producing the same weight of plastic from fossil feedstocks

.

Avangard Innovative is the largest plastics recycler in the United States and will be the first company in the United States to use the UpCycle process technology

.

Honeywell and Avangard will form a joint venture facility in the Natura PCR area in Waller, Texas, under common ownership and operation

.

The plant, which is expected to start production in 2023, will reuse 30,000 tons of waste per year as raw material for Honeywell's recycled polymers

.

"By partnering with companies with experience in recycling and waste management, Honeywell can help close the plastic supply chain by bringing recycling technologies to the source," said Vimal Kapur, president and CEO of Honeywell Performance Materials and Technologies.

"UpCycle technology expands the types of plastics that can be recycled, including those that cannot be recycled, allowing Honeywell to play a key role in driving a circular plastics economy

.

"

"By partnering with Honeywell to build an advanced recycling facility, Avangard innovation is able to achieve its goal of zero waste to landfill and strengthen its mission to protect the environment," said Rick Perez, CEO of Avangard innovation

.

"Honeywell's solution The scheme takes a modular approach to plant design, allowing for simple deployment and installation, while striking the right balance between economies of scale and the amount of plastic waste generated locally

.

”

Honeywell also recently announced its intention to form a joint venture with Spain's Sacyr.

The joint venture will be built in Andalucía, southern Spain.

The plant will have the capacity to reuse 30,000 tons of mixed waste plastics per year to produce as Honeywell Recycled Production capacity of polymer raw materials

Avangard Innovative is a global leader in technology-driven circular economy solutions

.

With 30 years of experience, operating in eleven countries, Avangard Innovative is the largest recycler in the United States and provides a full range of waste management and recycling process optimization solutions

.