-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Vegetable protein is derived from plants, similar to animal protein, and has comprehensive nutrition.

It is easily digested and absorbed by the human body and has health care functions

.

In order to develop the higher value of vegetable protein, we have developed vegetable protein freeze-drying technology, selected a food freeze-drying machine that meets the requirements of freeze-drying process, and carried out low-temperature freeze-vacuum drying of vegetable protein.

The nutrients and active substances of the original vegetable protein, and the color, fragrance, etc.

are basically unchanged, and can be stored at room temperature for a long time

.

It solves the problems that traditional liquid storage is difficult, transportation is difficult, circulation is difficult and inconvenient to use

.

The vegetable protein freeze-drying technology freezes the processed vegetable protein liquid into a solid at a low temperature of -45°C in a vegetable protein freeze-drying machine.

The temperature-controlled sublimation drying is carried out.

The temperature control range is -35~15°C.

The heating rate is controlled in stages.

It must be dried at the temperature of the eutectic point of the vegetable protein to remove most of the running water

.

After about 600 minutes of primary drying, analytical drying is carried out, the vacuum is controlled within 35PA, the temperature range is 20~50 °C, and the analytical drying time is about 660 minutes to remove the remaining bound water

.

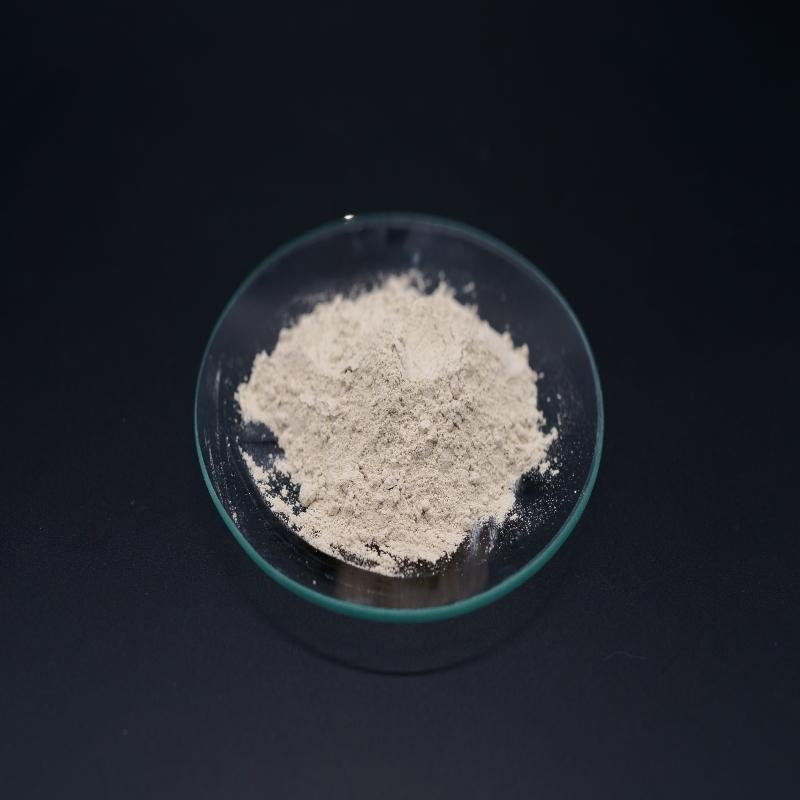

After three stages of pre-freezing, primary drying and analytical drying, vegetable protein freeze-dried powder with 1-3% water content is obtained, which preserves the original vegetable protein nutrients and active substances, and the original color, aroma and taste.

etc.

are basically unchanged

.

The choice of vegetable protein freeze-drying machine depends on the technical requirements of vegetable protein freeze-drying process.

Select a contact freeze-drying machine according to needs

.

Ultimate vacuum: 2.

5PA, the limit temperature of the condenser is -70°C, and the water capture capacity is more than 1.

5 times the standard capacity

.

The freeze-drying equipment needs to have freeze-drying process data setting, freeze-drying data recording and traceability, heating rate control and vacuum fine-tuning control, and remote operation and monitoring functions

.

Therefore, the plant freeze dryer can choose a pharmaceutical freeze dryer or a high-end contact food freeze dryer

.

It is easily digested and absorbed by the human body and has health care functions

.

In order to develop the higher value of vegetable protein, we have developed vegetable protein freeze-drying technology, selected a food freeze-drying machine that meets the requirements of freeze-drying process, and carried out low-temperature freeze-vacuum drying of vegetable protein.

The nutrients and active substances of the original vegetable protein, and the color, fragrance, etc.

are basically unchanged, and can be stored at room temperature for a long time

.

It solves the problems that traditional liquid storage is difficult, transportation is difficult, circulation is difficult and inconvenient to use

.

The vegetable protein freeze-drying technology freezes the processed vegetable protein liquid into a solid at a low temperature of -45°C in a vegetable protein freeze-drying machine.

The temperature-controlled sublimation drying is carried out.

The temperature control range is -35~15°C.

The heating rate is controlled in stages.

It must be dried at the temperature of the eutectic point of the vegetable protein to remove most of the running water

.

After about 600 minutes of primary drying, analytical drying is carried out, the vacuum is controlled within 35PA, the temperature range is 20~50 °C, and the analytical drying time is about 660 minutes to remove the remaining bound water

.

After three stages of pre-freezing, primary drying and analytical drying, vegetable protein freeze-dried powder with 1-3% water content is obtained, which preserves the original vegetable protein nutrients and active substances, and the original color, aroma and taste.

etc.

are basically unchanged

.

The choice of vegetable protein freeze-drying machine depends on the technical requirements of vegetable protein freeze-drying process.

Select a contact freeze-drying machine according to needs

.

Ultimate vacuum: 2.

5PA, the limit temperature of the condenser is -70°C, and the water capture capacity is more than 1.

5 times the standard capacity

.

The freeze-drying equipment needs to have freeze-drying process data setting, freeze-drying data recording and traceability, heating rate control and vacuum fine-tuning control, and remote operation and monitoring functions

.

Therefore, the plant freeze dryer can choose a pharmaceutical freeze dryer or a high-end contact food freeze dryer

.