-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Vanillin is a widely used flavoring agent in the food and beverage industry.

It is also used as a precursor in the production of various other chemicals.

The upstream and downstream products of vanillin are crucial in the chemical industry, and they have a significant impact on the overall production process.

In this article, we will discuss the upstream and downstream products of vanillin and their importance in the chemical industry.

Upstream Products of Vanillin

The upstream products of vanillin are the raw materials required for its production.

Vanillin is mainly extracted from vanilla beans, which are derived from the vanilla plant.

The vanilla plant is native to Mexico and is primarily grown in tropical regions.

The upstream products of vanillin include vanilla beans, cloves, and cinnamon, which are used to extract vanillin.

The vanilla beans are the primary source of vanillin.

They are harvested from the vanilla plant and are then processed to extract the flavoring agent.

The beans are first steamed to release the flavoring compounds, including vanillin.

The vanillin is then extracted using various solvents, such as water, ethanol, and methanol.

The extracted vanillin is then purified and dried to produce the final product.

Downstream Products of Vanillin

The downstream products of vanillin are the various chemicals that are produced using vanillin as a precursor.

Vanillin is used as a building block in the production of various flavor compounds, fragrances, and other chemicals.

The downstream products of vanillin are important in the flavor and fragrance industry, as well as in the production of pharmaceuticals, cosmetics, and other consumer products.

One of the most common downstream products of vanillin is vanilla flavor.

Vanillin is used to create the distinctive vanilla flavor and aroma that is widely used in food and beverage products.

Vanillin is also used in the production of other flavors, such as chocolate, caramel, and hazelnut.

It is also used in the production of fragrances and perfumes.

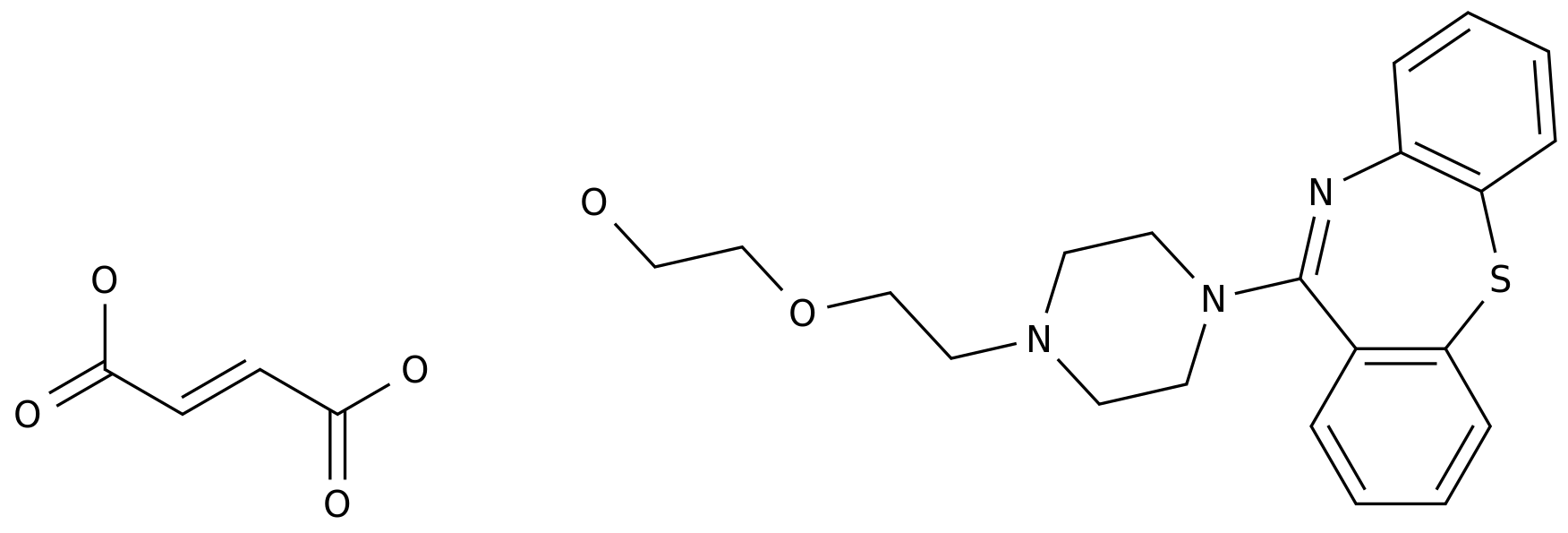

Another important downstream product of vanillin is pharmaceuticals.

Vanillin and its derivatives are used in the production of various drugs and medications.

For example, vanillin is used in the production of codeine, which is used as a pain reliever and cough suppressant.

It is also used in the production of other opioids, such as hydrocodone and oxycodone.

Vanillin is also used in the production of cosmetics, such as shampoos, conditioners, soaps, and lotions.

It is used to create the distinctive vanilla fragrance that is widely used in these products.

Challenges in Upstream and Downstream Production

The upstream and downstream production of vanillin presents several challenges.

One of the main challenges is the high cost of raw materials.

Vanilla beans are expensive, and the cost of extracting vanillin from them is also high.

This makes the production of vanillin expensive and less accessible for smaller companies.

Another challenge is the environmental impact of vanillin production.

Vanilla cultivation is associated with deforestation and the destruction of tropical forests.

This has led to calls for sustainable vanilla production methods to be developed.

Downstream products also present challenges.

The production of fragrances and flavors is a complex process that requires a significant amount of research and development.

The production of pharmaceuticals and other chemicals also requires significant investment in equipment and infrastructure.

The Future of Upstream and Downstream Production

The demand for vanillin and its downstream products is expected to grow in the coming years.

This is due to the increasing demand for natural flavors and fragrances in the food and beverage industry, as well as the growth of the personal care and pharmaceutical industries.

To meet this demand, there is a need for sustainable and efficient upstream production methods.

This includes the development of sustainable vanilla cultivation methods and the use of