-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

The chemical industry is constantly evolving and adapting to meet the demands of a changing world.

One of the essential chemicals in this industry is Sodium Bromide, which has numerous applications across various sectors.

Upstream and downstream are two crucial aspects of the chemical industry, and they play a vital role in the production and utilization of Sodium Bromide.

In this article, we will explore the Upstream and Downstream products of Sodium Bromide and their importance in the chemical industry.

Upstream Products of Sodium Bromide

The Upstream products of Sodium Bromide refer to the raw materials and intermediates that are used in the manufacturing process of Sodium Bromide.

The primary raw material used in the production of Sodium Bromide is rock salt or natural sodium chloride.

This raw material is refined to obtain sodium chloride, which is further reacted with hydrogen bromide gas to produce Sodium Bromide.

The hydrogen bromide gas used in the production of Sodium Bromide is also an Upstream product, and it is typically obtained from the reaction between hydrochloric acid and sodium hydroxide.

Other Upstream products used in the production of Sodium Bromide include reaction vessels, stirring mechanisms, and temperature control systems.

These components play a critical role in ensuring that the reaction between sodium chloride and hydrogen bromide proceeds smoothly and efficiently.

The quality of the Upstream products used in the production of Sodium Bromide directly affects the quality of the final product, and it is essential to ensure that all Upstream products meet the required standards and specifications.

Downstream Products of Sodium Bromide

The Downstream products of Sodium Bromide refer to the final products that are made using Sodium Bromide as a key ingredient.

Sodium Bromide is a versatile chemical that has numerous applications in various sectors.

Some of the most common Downstream products of Sodium Bromide include:

- Pesticides: Sodium Bromide is used in the production of various pesticides, including insecticides and fungicides.

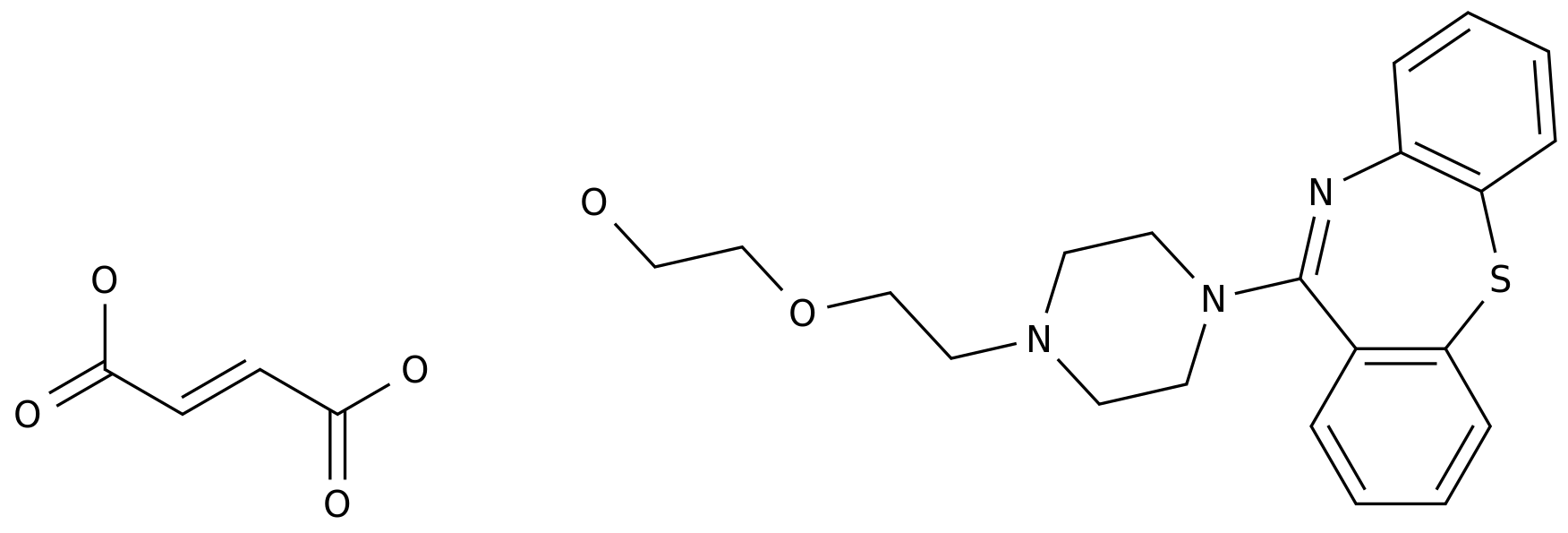

These pesticides are widely used in agriculture to protect crops from pests and diseases. - Pharmaceuticals: Sodium Bromide is used in the production of various pharmaceutical products, including tranquilizers, antiepileptic drugs, and sedatives.

- Fragrances: Sodium Bromide is used in the production of various fragrances, including perfumes and soaps.

- Textiles: Sodium Bromide is used in the production of various textiles, including rayon and viscose.

- Water treatment: Sodium Bromide is used in the treatment of water to remove impurities and disinfect the water.

The Downstream products of Sodium Bromide are used in various sectors, including agriculture, pharmaceuticals, textiles, and water treatment.

The demand for these products is constantly increasing, and the chemical industry is working to meet these demands by producing high-quality Sodium Bromide.

Challenges in the Production of Sodium Bromide

The production of Sodium Bromide involves several challenges, including the purification of raw materials, the control of reaction conditions, and the recovery and recycling of by-products.

These challenges can affect the quality and efficiency of the production process, and they must be addressed to ensure that the final product meets the required standards and specifications.

One of the key challenges in the production of Sodium Bromide is the purification of raw materials.

Rock salt, the primary raw material used in the production of Sodium Bromide, is often contaminated with impurities, such as iron oxide and calcium carbonate.

These impurities can affect the quality of the final product, and it is essential to remove them before the production process begins.

The purification process typically involves the use of various chemicals and physical methods, such as filtration and centrifugation.

Another challenge in the production of Sodium Bromide