-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Introduction

Today, the pharmaceutical industry is at the forefront of developing new drugs and therapies to improve human health.

In this regard, Liraglutide Acetate is a drug that has been widely researched and used for the treatment of various medical conditions.

In this article, we will explore the concept of upstream and downstream products in the chemical industry, particularly in the context of Liraglutide Acetate.

Upstream and Downstream Products

The upstream and downstream products are integral parts of the chemical industry, and they are closely related to the process of drug manufacturing.

Upstream products refer to the raw materials and intermediate chemicals that are used to produce the final drug.

Downstream products, on the other hand, are the finished drugs that are sold to pharmacies, hospitals, and other healthcare providers.

Liraglutide Acetate is an example of a drug that has both upstream and downstream products.

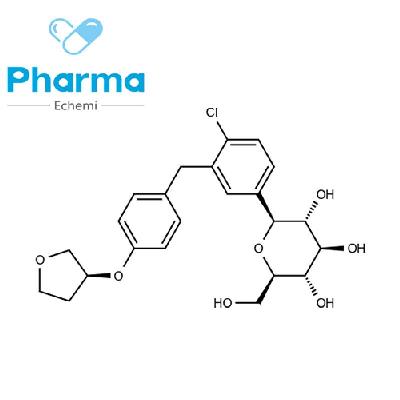

The upstream products for Liraglutide Acetate include the raw materials such as the active pharmaceutical ingredient (API) and excipients used in the manufacturing process.

The downstream products of Liraglutide Acetate include the finished drug that is sold to healthcare providers for use in the treatment of medical conditions.

Manufacturing Process

The manufacturing process of Liraglutide Acetate involves several stages, including research and development, synthesis, formulation, and packaging.

During the research and development stage, scientists discover and test various compounds to identify potential drugs.

Once a compound is identified, it undergoes synthesis, where it is chemically manufactured in the laboratory.

After synthesis, the compound is formulated into a final drug product that is ready for clinical testing.

The Manufacturing of Liraglutide Acetate

Liraglutide Acetate is synthesized through a multi-step process that involves several chemical reactions.

The process begins with the synthesis of the active pharmaceutical ingredient, which is then combined with excipients to form the final drug.

The excipients are often chosen for their ability to enhance the stability, solubility, and bioavailability of the drug.

After the final drug product is manufactured, it undergoes various quality control tests to ensure that it meets the required standards for safety and efficacy.

The packaging process involves the preparation of the drug in the appropriate dosage forms, such as tablets or injection, and the packaging of the drug into containers such as vials or syringes.

Conclusion

In conclusion, the manufacturing process of Liraglutide Acetate involves both upstream and downstream products.

The upstream products include the raw materials and intermediate chemicals used in the manufacturing process, while the downstream products are the finished drugs that are sold to healthcare providers.

Understanding the upstream and downstream products is essential for ensuring the quality and safety of the final drug product.

Effective supply chain management is also critical to ensure that the necessary raw materials and intermediates are available for the manufacturing process and that the finished drug products are delivered to healthcare providers in a timely and efficient manner.