-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Flunitrazepam is a benzodiazepine drug that is commonly used as a hypnotic, sedative, and anxiolytic agent.

It is primarily used to treat insomnia and other sleep disorders.

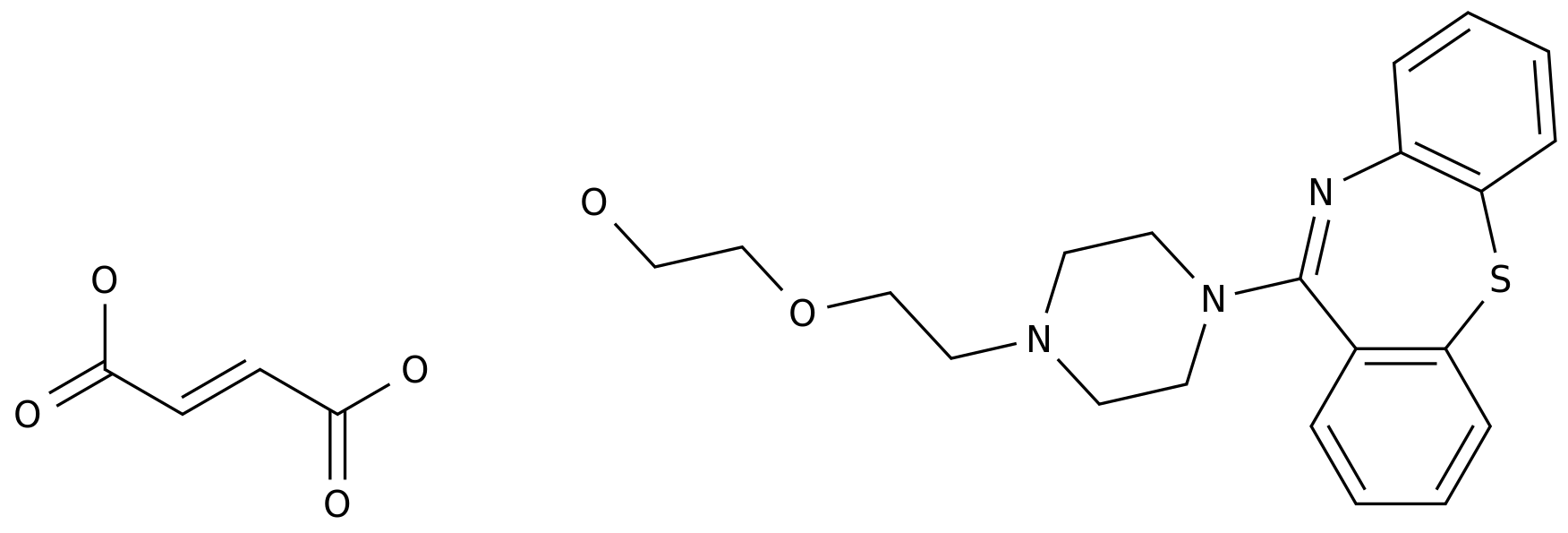

In the chemical industry, flunitrazepam is synthesized through a series of chemical reactions, and the process involves several intermediate products, which are known as upstream and downstream products.

Upstream products are the chemicals and reagents that are used in the synthesis of flunitrazepam.

These products are typically synthesized through a series of chemical reactions and purification steps.

The upstream products include precursors such as benzaldehyde, nitrobenzene, and piperazine.

These precursors are reacted with various reagents and catalysts to form the intermediate products.

The intermediate products of flunitrazepam synthesis include the substitution of the benzaldehyde ring with a nitrobenzene ring, followed by the substitution of the nitrobenzene ring with a piperazine ring.

The reaction steps involve the use of strong acids, bases, and reagents such as sodium hydroxide, hydrochloric acid, and hydrazine.

These reactions require careful purification and isolation of the intermediate products to avoid contamination and unwanted side reactions.

Downstream products are the final products that are obtained after the synthesis of flunitrazepam.

These products include the active pharmaceutical ingredient (API), which is the actual drug substance that is used in the treatment of sleep disorders.

The API is synthesized through a series of purification steps to remove impurities and to obtain a pure form of the drug.

The purification steps involve the use of various chromatographic techniques such as column chromatography and high-performance liquid chromatography (HPLC).

These techniques are used to separate the API from the other components of the reaction mixture.

The purified API is then formulated into dosage forms such as tablets, capsules, and liquids, which are used for the treatment of insomnia and other sleep disorders.

The production of flunitrazepam involves various manufacturing steps, including the synthesis of the upstream products and the downstream API.

The process is highly regulated by regulatory agencies such as the FDA to ensure the quality and safety of the final product.

The manufacturing process also involves various quality control measures such as testing for impurities, potency, and purity of the final product.

In conclusion, the production of flunitrazepam involves a series of upstream and downstream products, which are synthesized through a series of chemical reactions and purification steps.

The upstream products are the precursors that are used in the synthesis of the API, while the downstream products are the final product that is used in the treatment of sleep disorders.

The process of manufacturing flunitrazepam is highly regulated to ensure the quality and safety of the final product.