-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

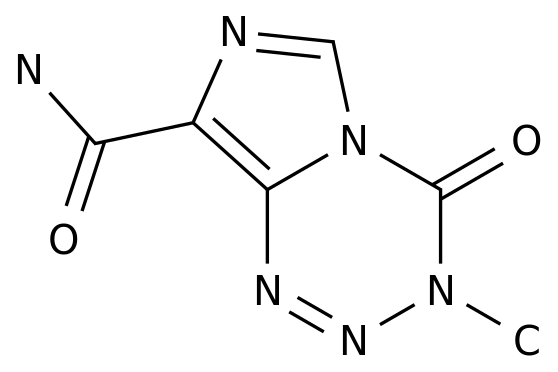

Erlotinib hydrochloride is an FDA-approved drug used to treat non-small cell lung cancer and pancreatic cancer.

The drug is a tyrosine kinase inhibitor that works by blocking the activity of the EGFR protein, which is involved in cell growth and division.

In the chemical industry, erlotinib hydrochloride is considered an important intermediate in the production of other pharmaceuticals, and it is also used in research and development.

Upstream Products

The production of erlotinib hydrochloride involves several upstream products, including the raw materials needed for its synthesis and the intermediates that are used in the process.

The primary raw materials used in the production of erlotinib hydrochloride include anthranilic acid, benzaldehyde, and pargyl alcohol.

These raw materials are derived from natural sources or are synthesized through chemical reactions.

Anthranilic acid is a derivative of DAPI (4',6'-diamidino-2-phenylindole), which is a commonly used fluorescent dye.

It is typically synthesized through the reaction of o-nitroaniline with potassium hydroxide.

Benzaldehyde, on the other hand, is derived from toluene through a series of chemical reactions known as the Williamson ether synthesis.

Pargyl alcohol, another key raw material, is produced through the reduction of pargyl bromide, which is obtained from the reaction between bromine and acetaldehyde.

Once the raw materials are obtained, they are used in the synthesis of erlotinib hydrochloride.

The process typically involves several steps, including the condensation of anthranilic acid and benzaldehyde to form an anthranilamide intermediate.

This intermediate is then treated with a series of reagents to form the erlotinib hydrochloride molecule.

The final product is a white to off-white powder that is soluble in water.

Downstream Products

Erlotinib hydrochloride is used as an intermediate in the production of other pharmaceuticals, and it is also used in research and development.

One of the most common downstream products is the combination therapy of erlotinib hydrochloride and bevacizumab, which is used to treat non-small cell lung cancer.

In this therapy, erlotinib hydrochloride is used to inhibit the EGFR protein, while bevacizumab is used to inhibit vascular endothelial growth factor (VEGF).

This combination therapy has been shown to be effective in improving patient outcomes.

Erlotinib hydrochloride is also used as a research tool in the study of cell signaling and cancer biology.

It is used to inhibit the EGFR protein and to study its effects on cell growth and division.

The knowledge gained from these studies can be used to develop new therapies for the treatment of cancer.

In addition to its use in the pharmaceutical industry, erlotinib hydrochloride is also used as a reagent in chemical synthesis.

It is used as a building block for the synthesis of other molecules, and it is also used as a catalyst for chemical reactions.

Challenges

The production of erlotinib hydrochloride involves several challenges, including the purification of the final product and the control of the reaction conditions.

The synthesis of erlotinib hydrochloride involves several steps, and each step must be carefully controlled to ensure the purity of the final product.

This is particularly important for the production of pharmaceutical-grade erlotinib hydrochloride, which must meet strict quality standards.

The control of the reaction conditions is also critical for the production of erlotinib hydrochloride.

The reaction conditions must be carefully controlled to ensure that the desired product is formed and that undesired side products are minimized.

This requires the use of specialized equipment and the optimization of reaction conditions through trial and error.

Conclusion

Erlotinib hydrochloride is an important intermediate in the production of other pharmaceuticals and is also used in research and development.

The production of erlotinib hydrochloride involves several upstream and downstream products, including raw materials and intermediates as well as