-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

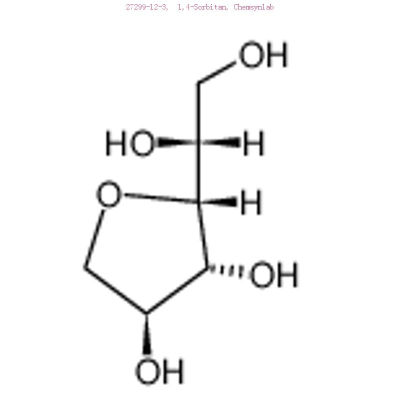

Trehalose, a naturally occurring disaccharide, has attracted significant attention in the chemical industry due to its unique physicochemical properties, such as high water solubility, thermal stability, and low hygroscopicity.

These properties make trehalose a promising candidate for various applications, including pharmaceuticals, food ingredients, and cosmetics.

One of the key challenges in the industrial production of trehalose is the high cost of the raw material, sucrose, which is used as the starting material for the synthesis of trehalose.

To address this challenge, various synthetic routes for trehalose have been developed over the years, aimed at reducing the cost and increasing the efficiency of the production process.

One of the most common synthetic routes for trehalose involves the use of sucrose, which is first hydrolyzed to glucose and fructose using acid or enzymes.

The glucose and fructose are then reconverted into sucrose, and the resulting sucrose is then hydrogenated to form trehalose.

This route is relatively simple and straightforward, but it suffers from some drawbacks, such as the need for a large amount of hydrogen gas, high energy consumption, and the production of excess hydrogen gas, which can be environmentally problematic.

Another synthetic route for trehalose involves the use of the enzyme glucose isomerase, which converts glucose into fructose.

The resulting fructose is then converted into trehalose using a series of chemical reactions, including reduction, acetylation, and hydrolysis.

This route is more efficient and environmentally friendly than the previous route, as it does not require hydrogenation and produces less excess hydrogen gas.

A more recent synthetic route for trehalose involves the use of microbial fermentation, where microorganisms are genetically engineered to produce trehalose as a byproduct of their metabolism.

This route is considered to be the most sustainable and environmentally friendly, as it does not involve the use of chemical reactions or hydrogenation, and the production process can be carried out at low temperatures and pressures.

In addition to the above-mentioned synthetic routes, there are also some other methods for the production of trehalose, such as the enzymatic hydrolysis of sucrose or the synthesis of trehalose from glucose and fructose using chemical reactions.

Overall, the synthetic routes for trehalose have evolved over the years, with the aim of reducing costs and increasing efficiency and sustainability.

The choice of synthetic route depends on various factors, such as the scale of production, the purity of the desired product, and the availability of raw materials.

As the demand for trehalose continues to grow, it is likely that new and more efficient synthetic routes will be developed to meet the needs of the chemical industry.