-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

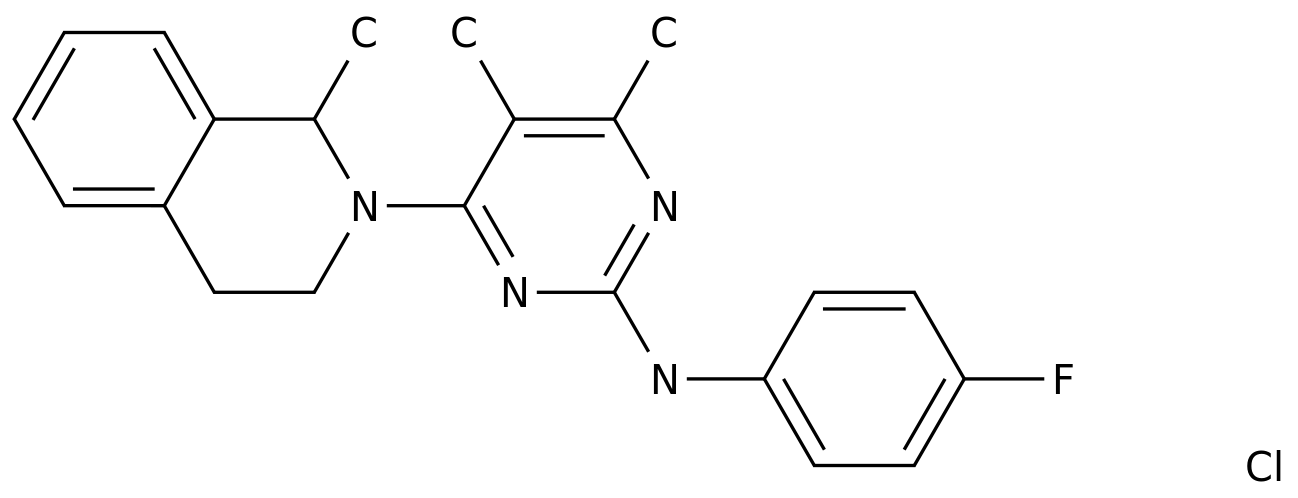

Ranitidine, a widely used antiulcer drug, is synthesized through various synthetic routes.

The most common synthetic route is through the reaction of 2-hydroxy-1,2,3,4-tetrahydro-beta-carboline-3-carboxylic acid with chloroacetone in the presence of a strong base, such as sodium hydroxide.

The reaction leads to the formation of the required ranitidine intermediate, which is then hydrolyzed in a basic medium to afford the final product, ranitidine hydrochloride.

Another synthetic route involves the reduction of nitric acid with sodium borohydride in the presence of a solvent, such as ethanol, to form the ranitidine intermediate.

This intermediate is then treated with chloroacetone in the presence of a base, such as sodium hydroxide, to form the desired product, ranitidine hydrochloride.

A third synthetic route for ranitidine involves the reaction of 2-amino-1,2,3,4-tetrahydro-beta-carboline-3-carboxylic acid with chloroform in the presence of a base, such as sodium hydroxide.

The reaction leads to the formation of the required intermediate, which is then treated with chloroacetone in the presence of a base, such as sodium hydroxide, to form ranitidine hydrochloride.

All these synthetic routes involve the use of harsh chemicals and require careful handling to prevent any accidents.

In addition, they involve several steps, which can increase the cost of production.

Therefore, there is a need for more efficient and cost-effective synthetic routes for ranitidine.

One of the newer synthetic routes for ranitidine involves the use of microwave irradiation to speed up the reaction rate.

In this route, the reaction of 2-hydroxy-1,2,3,4-tetrahydro-beta-carboline-3-carboxylic acid with chloroacetone in the presence of sodium hydroxide is carried out under microwave irradiation.

The shorter reaction time achieved through microwave irradiation results in a higher yield of the desired product, ranitidine hydrochloride.

Another newer synthetic route involves the use of green chemistry principles.

In this route, the reaction of 2-hydroxy-1,2,3,4-tetrahydro-beta-carboline-3-carboxylic acid with chloroacetone in the presence of sodium hydroxide is carried out using solvent-free conditions.

The use of solvent-free conditions not only reduces the environmental impact of the reaction but also reduces the cost of production.

The product, ranitidine hydrochloride, is obtained in good yield through this route.

In conclusion, there are several synthetic routes for ranitidine, including those involving harsh chemicals and several steps.

However, newer synthetic routes, such as those involving microwave irradiation and green chemistry principles, offer the promise of increased efficiency and cost-effectiveness.

The use of these newer synthetic routes has the potential to improve the production of ranitidine, making it more accessible and affordable for patients in need.