-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Introduction:

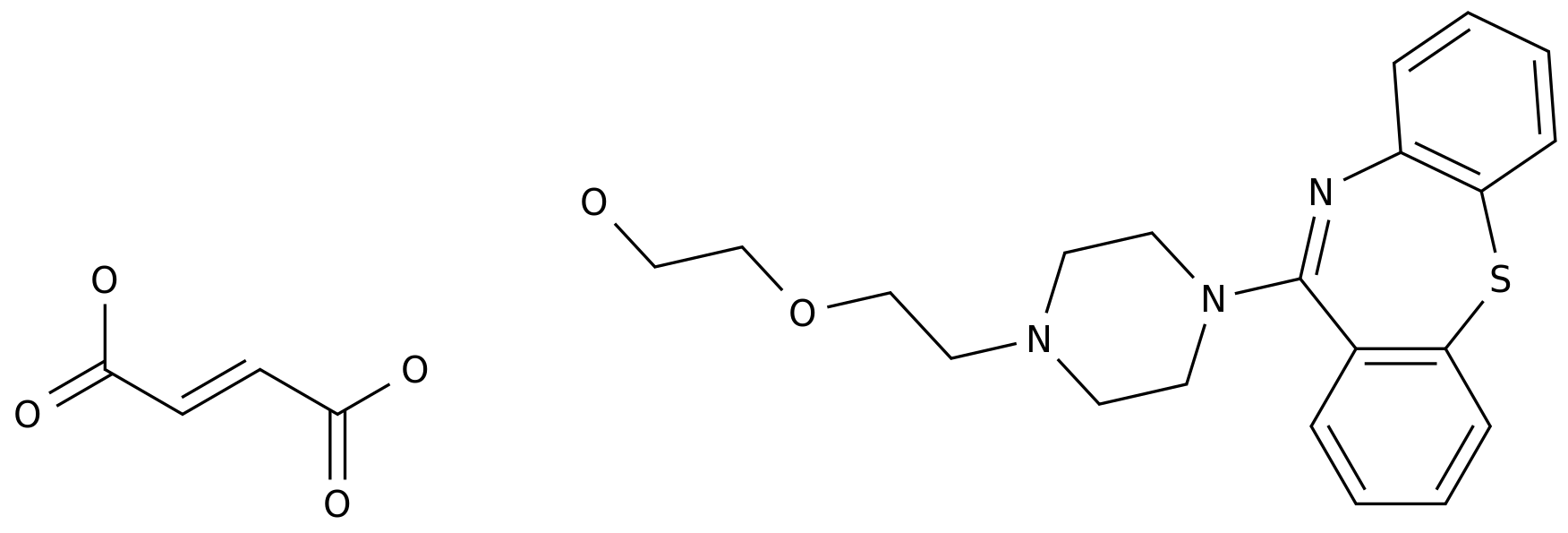

Molindone is an antipsychotic drug that is commonly used to treat schizophrenia and other psychiatric disorders.

It is a synthetic compound that is derived from a natural product known as streptomycin.

There are several synthetic routes that have been developed for the production of molindone, some of which are more efficient than others.

In this article, we will discuss some of the most commonly used synthetic routes for the production of (±)-molindone.

Synthetic Route 1: The Nitro-Methylation Route

The nitro-methylation route is one of the most commonly used synthetic routes for the production of molindone.

This route involves the nitration of methylstyrene with nitric acid to produce 4-nitro-1,2-dimethylbenzene.

This compound is then treated with sodium hydroxide to convert it to 4-amino-1,2-dimethylbenzene.

This compound is then treated with chloroform and an aqueous solution of hydrochloric acid to produce 4-chloro-1,2-dimethylbenzene.

This compound is then treated with diethyl sulfate and a base to produce 4-(2-methoxyethoxy)-1,2-dimethylbenzene.

This compound is then treated with a solution of hydrochloric acid and a base to produce 4-(2-methoxyethoxy)-1,2-dimethylbenzene.

This compound is then treated with ammonia and a solvent to produce (±)-molindone.

Synthetic Route 2: The Electrophilic Substitution Route

The electrophilic substitution route is another commonly used synthetic route for the production of molindone.

This route involves the reaction of 4-chloro-1,2-dimethylbenzene with sodium hydroxide to produce 4-(2-hydroxyethoxy)-1,2-dimethylbenzene.

This compound is then treated with an aqueous solution of hydrochloric acid and sodium chlorite to produce 4-(2-hydroxyeth