-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

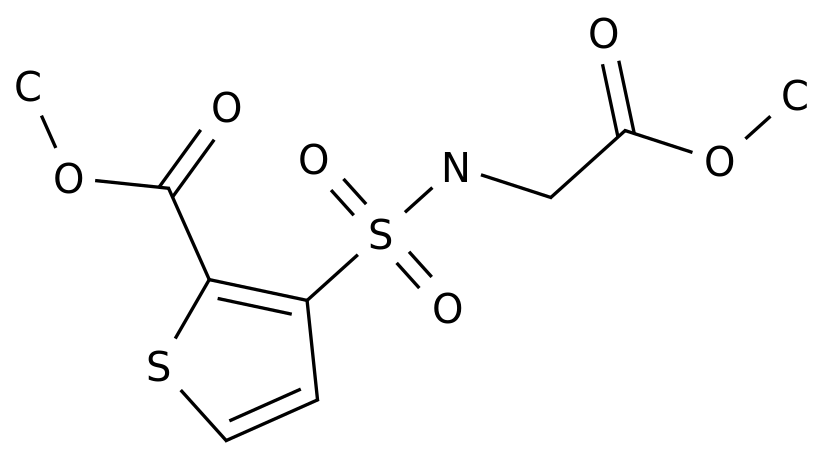

The synthetic routes of methyl-2-isothiocyanatothiophene-3-carboxylate, commonly referred to as MCC, are numerous and varied, and the choice of route depends on a variety of factors, including the desired purity and yield of the product, the available starting materials, and the scale of the production.

In this article, we will discuss some of the most commonly used synthetic routes for MCC in the chemical industry.

- The Hydrolysis of Nitrobiphenyl-2-carboxylate

One of the most common methods for the synthesis of MCC is the hydrolysis of nitrobiphenyl-2-carboxylate, which is a compound that can be synthesized by a variety of methods, including the nitration of biphenyl with nitric acid.

The nitrobiphenyl-2-carboxylate is then treated with a strong base, such as sodium hydroxide or potassium hydroxide, in the presence of a solvent, such as water or ethanol, to produce MCC.

This method is simple and straightforward, and the product can be purified by filtering or by using a solvent with a higher boiling point.

- The Reaction of Methyl Ionone with Thiophenol-3-sulfonic Acid

MCC can also be synthesized by the reaction of methyl ionone with thiophenol-3-sulfonic acid.

Methyl ionone is a compound that is easily accessible and relatively inexpensive, and thiophenol-3-sulfonic acid can be synthesized by a variety of methods, including the reaction of thiophenol with sulfuric acid.

The reaction between methyl ionone and thiophenol-3-sulfonic acid produces MCC and a byproduct, which can be removed by filtration or by using a solvent that has a lower boiling point than the boiling point of the byproduct.

- The Reaction of Chloroform with Sodium Hydrosulfide

Another method for the synthesis of MCC is the reaction of chloroform with sodium hydrosulfide.

Chloroform is a readily available starting material, and sodium hydrosulfide can be synthesized by a variety of methods, including the reaction of sodium hydroxide with hydrogen sulfide.

The reaction between chloroform and sodium hydrosulfide produces MCC and a byproduct, which can be removed by filtration or by using a solvent that has a lower boiling point than the boiling point of the byproduct.

- The Reaction of Bromobenzene with Thiophenol

MCC can also be synthesized by the reaction of bromobenzene with thiophenol.

Bromobenzene is a commonly used starting material in the chemical industry, and thiophenol can be synthesized by a variety of methods.

The reaction between bromobenzene and thiophenol produces MCC and a byproduct, which can be removed by filtration or by using a solvent that has a lower boiling point than the boiling point of the byproduct.

In conclusion, the synthetic routes of MCC are numerous and varied, and the choice of route depends on a variety of factors, including the desired purity and yield of the product, the available starting materials, and the scale of the production.

The methods described above are just a few of the many methods that are used in the chemical industry for the synthesis of MCC.

By understanding the different synthetic routes, it is possible to select the most appropriate method for a particular application, and to optimize the synthesis process for maximum efficiency and yield.