-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

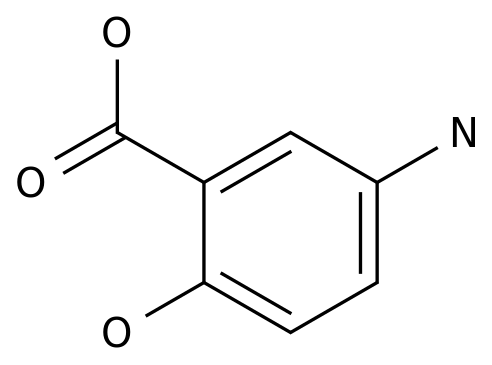

Malonate is an organic compound with the molecular formula C4H6O5.

It is a versatile intermediate in the production of a wide range of chemicals, including plastics, dyes, and pharmaceuticals.

One of the most commonly used synthetic routes for malonate is the catalytic hydrogenation of m-xylene, which is a colorless liquid with a characteristic sweet odor.

The process of hydrogenation involves the reaction of the m-xylene with hydrogen gas in the presence of a catalyst.

The reaction takes place in a series of stages, with the m-xylene first being converted to benzaldehyde and then to benzoic acid.

The benzoic acid is then hydrogenated to produce malonate.

The hydrogenation process requires the use of a catalyst, such as palladium on barium oxide, to facilitate the reaction.

The reaction temperature and pressure are carefully controlled to optimize the yield and purity of the malonate product.

The resulting malonate product is a white, crystalline solid that is used as an intermediate in the production of a wide range of chemicals.

In addition to the hydrogenation of m-xylene, other synthetic routes to malonate include the oxidation of cyclohexane and the condensation of formaldehyde and acetaldehyde.

These routes are typically more complex and require the use of specialized equipment and reagents, and may also produce by-products that need to be separated and disposed of.

The use of malonate as an intermediate in the production of chemicals has a long history, dating back to the early 20th century.

Its versatility and stability make it a valuable building block for a wide range of chemicals, including alkyl resins, phenolic resins, and polyesters.

The chemical industry is a major consumer of malonate, with a variety of companies producing and using this chemical in their manufacturing processes.

The demand for malonate is expected to continue to grow in the coming years, driven by the increasing demand for plastics and other synthetic materials in a variety of industries, including the automotive, electronics, and packaging industries.

In addition to its use in the production of chemicals, malonate has also been found to have potential uses in the pharmaceutical industry.

Research has shown that malonate may have antimicrobial and antioxidant properties, making it a potential ingredient in topical medications and other products.

Despite its widespread use and potential applications, malonate is not without its drawbacks.

The production and use of this chemical can have a significant environmental impact, as the manufacturing process can generate waste and emissions that can have harmful effects on the environment.

Additionally, the use of malonate in the production of certain chemicals can have negative impacts on human health, such as exposure to toxic chemicals and the risk of cancer.

Overall, the synthetic routes of malonate are varied and may involve the use of hazardous reagents and chemicals.

The production and use of this chemical should be carefully managed to minimize its environmental and health impacts.

As technology continues to advance and new methods for the production of malonate are developed, it is important to consider the potential risks and benefits of these methods in order to ensure the safe and sustainable production of this important intermediate chemical.