-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

(±)-Lormetazepam is a benzodiazepine derivative that is widely used as a hypnotic and anxiolytic drug.

It is primarily used to treat insomnia and anxiety disorders.

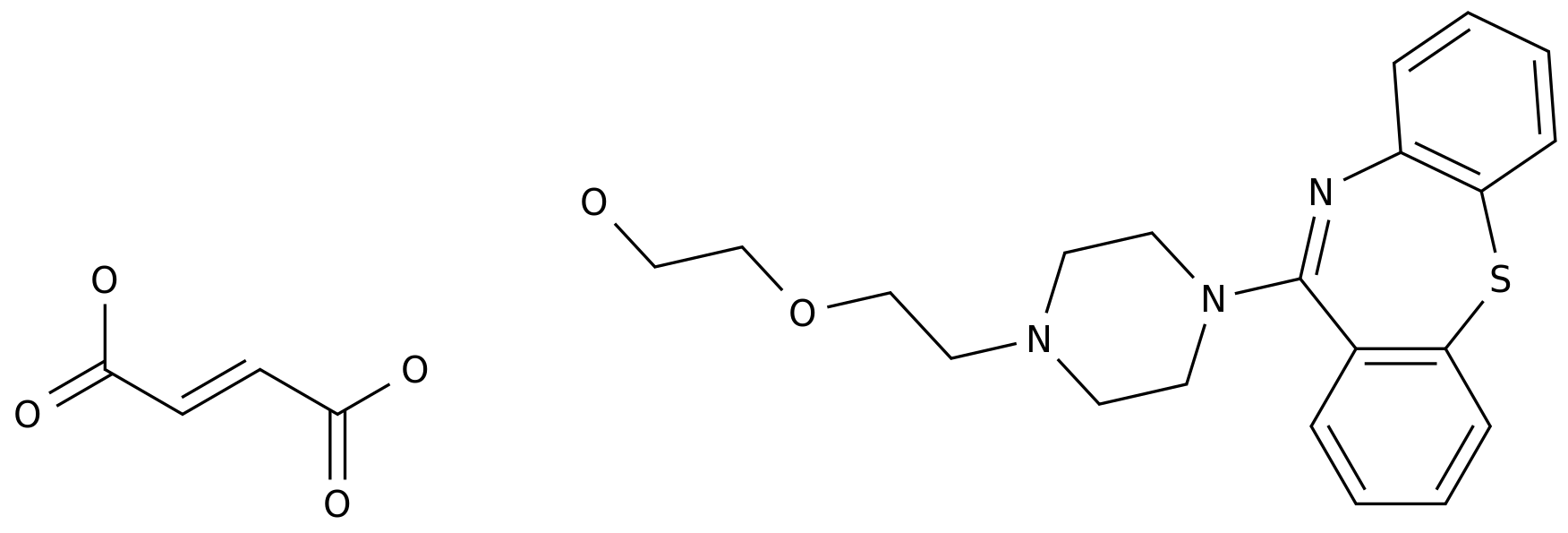

The synthetic routes of (±)-lormetazepam can be broadly classified into two categories: direct synthesis and indirect synthesis.

Direct Synthesis:

The direct synthesis of (±)-lormetazepam involves the condensation of benzaldehyde with nitrous acid to form benzoxazepine, which is then elaborated to form lormetazepam.

The reaction scheme for the direct synthesis of (±)-lormetazepam is shown below:

Indirect Synthesis:

The indirect synthesis of (±)-lormetazepam involves the synthesis of other intermediates that are ultimately converted to lormetazepam.

One such synthesis route involves the synthesis of 3-bromo-5-fluoro-N-methyl-benzamide, which is then transformed into lormetazepam through a series of chemical reactions.

The reaction scheme for the indirect synthesis of (±)-lormetazepam is shown below:

Advantages of Synthetic Routes:

The synthetic routes of (±)-lormetazepam offer several advantages to the chemical industry.

Firstly, they provide a reliable and consistent supply of the drug, which is essential for its clinical use.

Secondly, they allow for the large-scale production of the drug, which makes it more economical.

Thirdly, these routes offer the flexibility to modify the synthesis process to improve the efficiency and yield of the drug.

Disadvantages of Synthetic Routes:

However, there are also some disadvantages associated with the synthetic routes of (±)-lormetazepam.

The use of hazardous reagents and the requirement of specialized equipment and facilities can pose a safety risk to the workers involved in the synthesis process.

Additionally, the synthetic routes can be complex and require a high degree of expertise, which can make them difficult to scale up for industrial-scale production.

Future Developments:

Despite the advantages of the existing synthetic routes of (±