-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

The Synthesis of Dde-Lys(Fmoc)-OH: A Critical Overview of Current Methods in the Chemical Industry

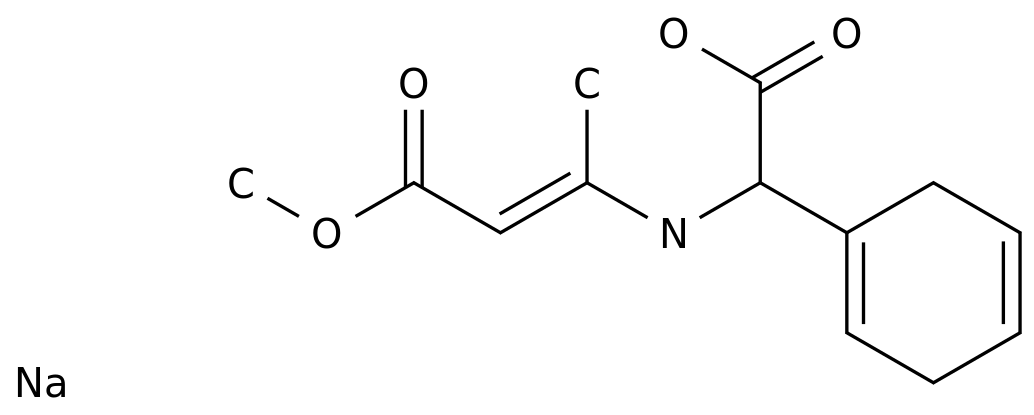

Dde-Lys(Fmoc)-OH is a key intermediate in the synthesis of various pharmaceuticals, agrochemicals, and fine chemicals.

The demand for this compound has been steadily increasing in the chemical industry due to its wide range of applications.

The synthesis of Dde-Lys(Fmoc)-OH can be achieved through several routes, each with its own advantages and limitations.

In this article, we will review the most commonly used synthetic routes for Dde-Lys(Fmoc)-OH and discuss their merits and drawbacks.

Route 1: Via the aldol reaction

The aldol reaction is a popular method for the synthesis of Dde-Lys(Fmoc)-OH.

This route involves the reaction of an aldehyde with a ketone or an ester in the presence of a Lewis acid catalyst.

The reaction produces a mixture of products, including Dde-Lys(Fmoc)-OH, which can be separated and purified using chromatography techniques.

This route is relatively simple and can be performed with easily available reagents.

However, the yield of Dde-Lys(Fmoc)-OH can be low, and the purification process can be time-consuming and expensive.

Route 2: Via the Wittig reaction

The Wittig reaction is another commonly used method for the synthesis of Dde-Lys(Fmoc)-OH.

This reaction involves the reaction of an aldehyde with a phosphorus ylide in the presence of a base.

The reaction produces a mixture of products, including Dde-Lys(Fmoc)-OH, which can be separated and purified using chromatography techniques.

The Wittig reaction is generally more efficient than the aldol reaction and can produce higher yields of Dde-Lys(Fmoc)-OH.

However, the reaction requires the use of expensive reagents and specialized equipment, and the purification process can still be time-consuming and expensive.

Route 3: Via the hydrolysis of an N-Boc-Lysine derivative

Another route for the synthesis of Dde-Lys(Fmoc)-OH involves the hydrolysis of an N-Boc-Lysine derivative.

This route involves the protection of the amino group of Lysine with a Boc group and the subsequent hydrolysis of the Boc group using hydrochloric acid.

The reaction produces Dde-Lys(Fmoc)-OH, which can be purified using chromatography techniques.

This route is relatively simple and can be performed with easily available reagents.

However, the yield of Dde-Lys(Fmoc)-OH can be low, and the purification process can be time-consuming and expensive.

Route 4: Via the three-step sequence

The three-step sequence is a synthetic route that involves the synthesis of Dde-Lys(Fmoc)-OH through three distinct stages.

The first stage involves the synthesis of an N-Boc-Lysine derivative, which is then converted into an N-Fmoc-Lysine derivative in the second stage.

The final stage involves the hydrolysis of the Fmoc group to produce Dde-Lys(Fmoc)-OH.

This route is more efficient than the other routes and can produce higher yields of Dde-Lys(Fmoc)-OH.

However, the route requires the use of expensive reagents and specialized equipment.

In conclusion, the synthesis of Dde-Lys(Fmoc)-OH is an important process in the chemical industry, with various synthetic routes available.

Each route has its own advantages and limitations, and the choice of route depends on various factors, including the availability of reagents, the yield of the desired product, and the cost of purification.

The three-