-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Introduction:

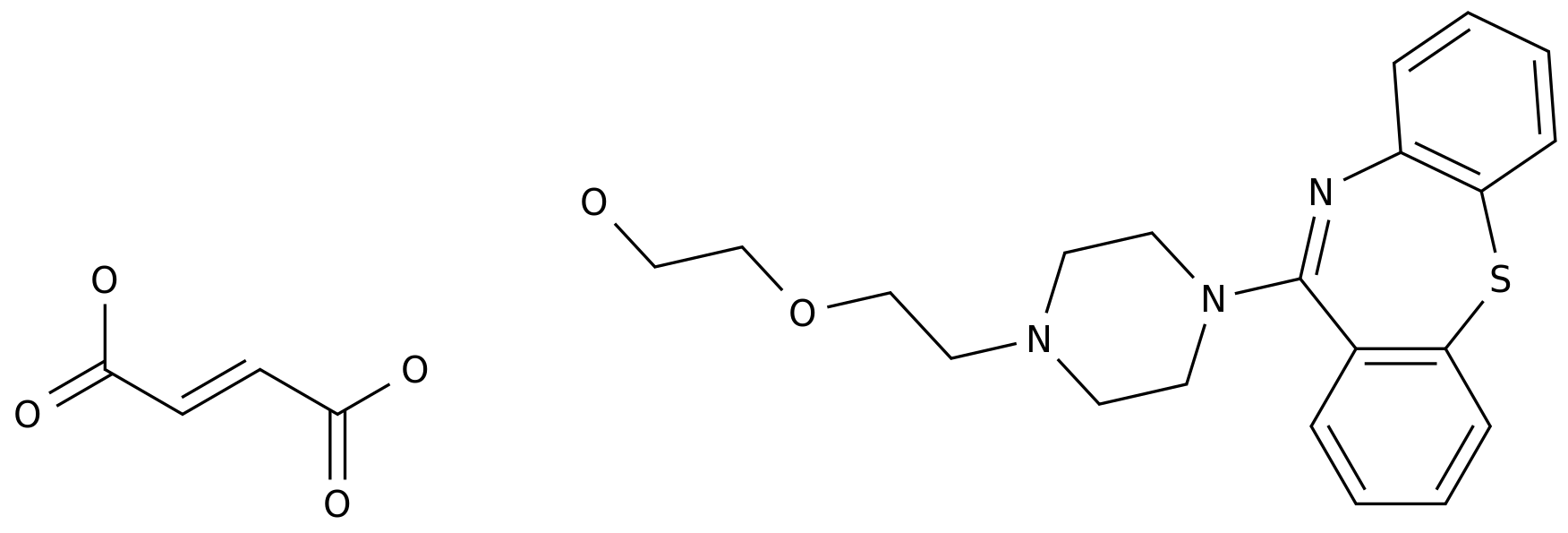

Biperiden lactate, also known as Bisoprolol fumarate, is a widely used antihypertensive medication in the pharmaceutical industry.

It is used to treat high blood pressure and heart failure.

The demand for Biperiden lactate has been increasing over the years due to its effectiveness in treating cardiovascular diseases.

This has led to the development of various synthetic routes for the production of Biperiden lactate.

In this article, we will discuss some of the commonly used synthetic routes for the production of Biperiden lactate.

Synthetic routes for Biperiden lactate:

- Classic route: The classic route for the synthesis of Biperiden lactate involves the use of several chemical reactions, such as the Vilna-Huggins reaction, the Kochi-Hayashi reaction, and the Duane-Eubanks reaction.

The reaction sequence involves the formation of an intermediate, which is then modified to produce the final product. - Direct route: The direct route for the synthesis of Biperiden lactate involves the use of a single chemical reaction to produce the final product.

This route is simpler and more efficient than the classic route.

The reaction involves the fusion of two molecules to form a new bond, followed by the removal of a protecting group. - Hydrolysis route: The hydrolysis route for the synthesis of Biperiden lactate involves the use of water to break down an intermediate compound into the final product.

This route is also simple and efficient and involves fewer steps compared to the classic route.

Advantages of synthetic routes for Biperiden lactate:

- Cost-effective: The synthetic routes for Biperiden lactate are cost-effective, as they involve fewer steps and the use of less expensive reagents compared to the classic route.

- High yield: The synthetic routes for Biperiden lactate have a high yield, which results in a higher quantity of the final product being produced.

- Purity: The synthetic routes for Biperiden lactate produce a pure product, which is essential for pharmaceutical applications.

Conclusion:

The synthetic routes for Biperiden lactate have revolutionized the production of this antihypertensive medication.

The classic route, direct route, and hydrolysis route are some of the commonly used synthetic routes for the production of Biperiden lactate.

These routes offer several advantages, such as cost-effectiveness, high yield, and purity, making them ideal for pharmaceutical applications.

The demand for Biperiden lactate is expected to increase in the future, and the development of new and efficient synthetic routes will play a crucial role in meeting this demand.