-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

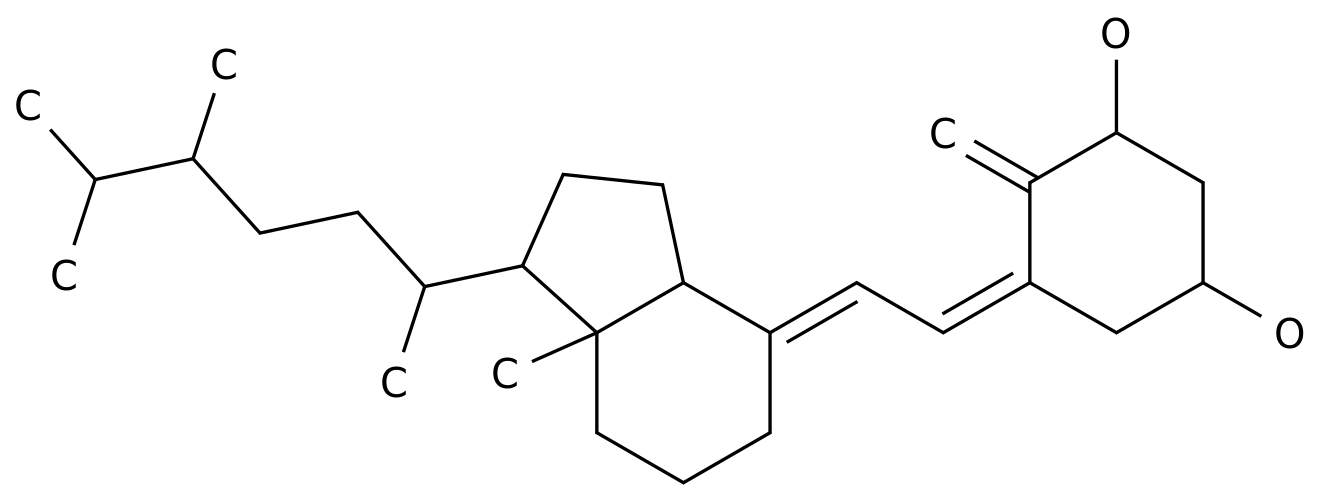

The synthesis of 10,10'-dibromo-9,9'-bianthryl, a versatile synthetic building block, has been a topic of extensive research in the chemical industry.

The bianthryl molecule is of particular interest due to its unique properties, such as its high chemical stability and fluorescence.

In this article, we will explore the different synthetic routes of 10,10'-dibromo-9,9'-bianthryl and highlight their applications in the chemical industry.

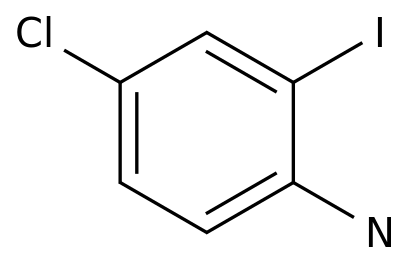

- The traditional synthetic route of 10,10'-dibromo-9,9'-bianthryl involves a multi-step process that involves the reaction of 2,2'-dibromo-4,4'-diaminobiphenyl with 9,9'-bianthryl chloride.

This route is commonly used in the chemical industry, as it provides good yields of the final product.

However, it is also a time-consuming and costly process, as it requires several steps to achieve the desired product. - Another synthetic route of 10,10'-dibromo-9,9'-bianthryl is through the reaction of 2,2'-dibromo-4,4'-diaminobiphenyl with 9,9'-bis(2,5-dibromopyrrolidin-1-yl)fluorene.

This route offers a more efficient synthetic pathway, as it reduces the number of steps required for synthesis.

Additionally, it results in a higher yield of the final product, making it a more economical process in the long run.

3