-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

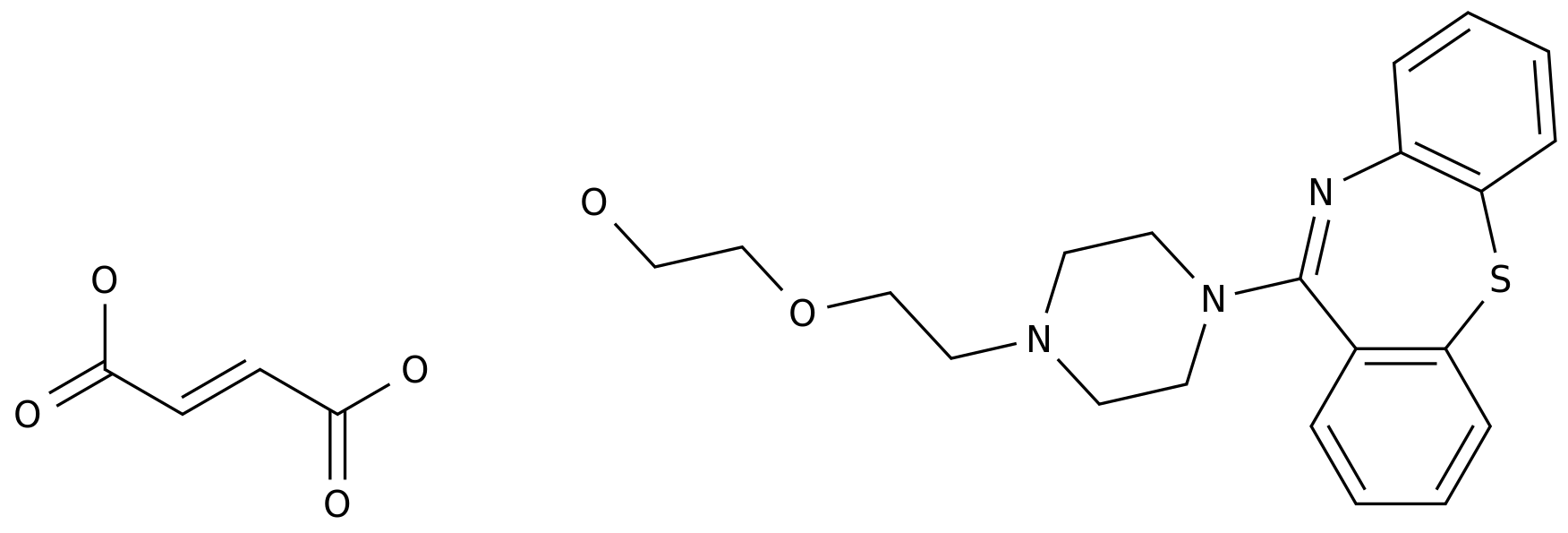

Zopiclone is a popular prescription medication used to treat insomnia and other sleep disorders.

The production process of zopiclone involves several steps, each of which requires careful attention to detail to ensure the final product is safe and effective.

In this article, we will provide an overview of the production process of zopiclone, from the synthesis of the active ingredient to the final packaging and distribution of the drug.

Step 1: synthesis of the active ingredient

The first step in the production of zopiclone involves the synthesis of the active ingredient, which is called zopiclone hydrochloride.

This is achieved by reacting a chemical called phenylcyclohexylamine with another chemical called chloroacetamide in the presence of a solvent such as dichloromethane.

The reaction is carefully monitored to ensure that it is proceeding as expected, and the resulting product is then purified through a series of chemical reactions and filtration steps.

Step 2: purification of the active ingredient

Once the active ingredient has been synthesized, it must be purified to remove any impurities that may have been introduced during the synthesis process.

This is typically achieved through a series of chromatographic techniques, such as column chromatography or high-performance liquid chromatography (HPLC).

These techniques involve passing the mixture of chemicals through a column that contains a stationary phase, such as silica gel or alumina, which selectively traps the impurities while allowing the pure product to pass through.

The purified active ingredient is then collected and further processed.

Step 3: formulation of the drug

Once the active ingredient has been purified, it is combined with other chemicals to create the final formulation of the drug.

This typically involves adding excipients, such as fillers, binders, and lubricants, to help the drug flow better and maintain its stability.

The formulation is then mixed thoroughly to ensure that all of the ingredients are well-dispersed.

Step 4: capsule filling

The final formulation is then placed into empty capsules, which are carefully weighed and measured to ensure that they contain the correct amount of drug.

The capsules are then sealed and packaged for distribution.

Quality control

Throughout the production process, quality control tests are conducted to ensure that the final product meets all of the necessary standards for safety and effectiveness.

These tests may include chemical analysis to verify the purity of the active ingredient, as well as tests to determine the drug's shelf life, stability, and bioavailability.

Only those batches of product that meet all of these standards are released for distribution.

Conclusion

The production process of zopiclone is a complex and multi-step process that requires careful attention to detail and a thorough understanding of the chemical reactions and processes involved.

From the synthesis of the active ingredient to the final packaging and distribution of the drug, each step must be carefully controlled and monitored to ensure that the final product is safe and effective.

By following these steps, pharmaceutical companies can produce high-quality medications like zopiclone that can help improve the lives of people around the world.