-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Tocopherol nicotinate, also known as vitamin E nicotinate, is a commonly used vitamin supplement that is derived from the natural mixture of tocopherols and nicotinic acid.

The production process of tocopherol nicotinate involves a series of chemical reactions that transform these raw materials into the final product.

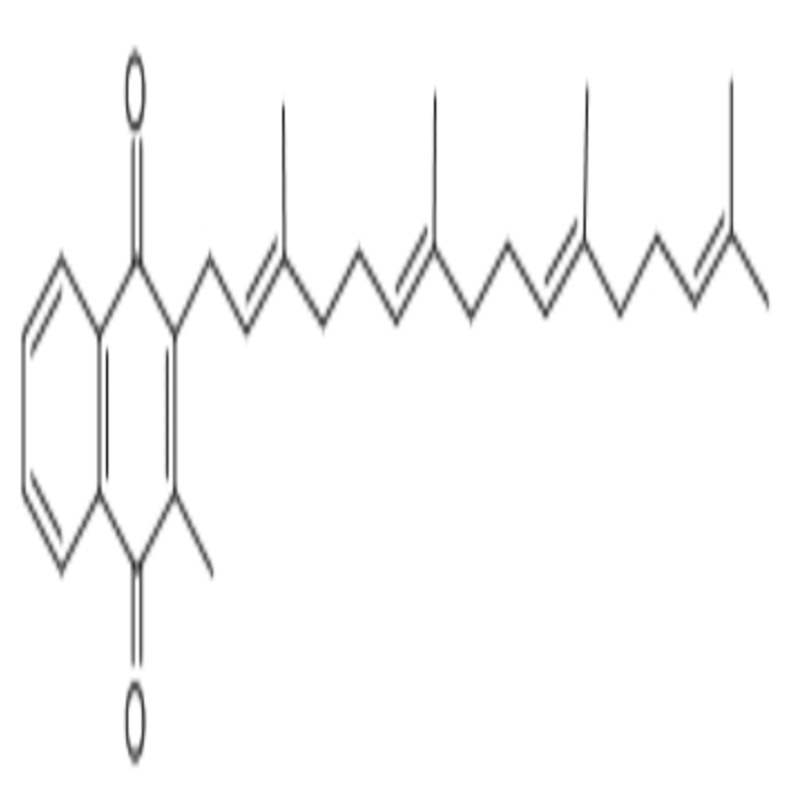

The first step in the production process of tocopherol nicotinate is the isolation of tocopherols from natural sources, such as vegetable oils or animal fats.

This is typically done through a process known as fractional distillation, which involves heating the raw material and then cooling and collecting the various fractions that have different boiling points.

The tocopherols are then further purified through a process known as chromatography, which separates the different types of tocopherols based on their chemical properties.

Once the tocopherols have been purified, they are then mixed with nicotinic acid in a specific ratio.

Nicotinic acid is commonly derived from the natural source of tobacco, but it can also be synthesized in the laboratory.

The mixing of tocopherols and nicotinic acid can be done through various methods, including blending, granulation, and extrusion.

The next step in the production process of tocopherol nicotinate is the reaction of the tocopherols and nicotinic acid in the presence of a chemical catalyst.

This reaction is known as esterification and it involves the formation of an ester between the alcohol group of the tocopherols and the acid group of the nicotinic acid.

This reaction is typically carried out in a reactor, which is a large glass or stainless steel vessel that is equipped with agitators and a heating system.

The temperature and agitation speed are carefully controlled to ensure that the reaction proceeds smoothly and efficiently.

After the esterification reaction is complete, the resulting product is then purified through a process known as crystallization.

This involves cooling the mixture to a temperature at which the tocopherol nicotinate separates out into a solid form.

The solid is then collected and dried to remove any remaining impurities.

The final step in the production process of tocopherol nicotinate is the packaging and distribution of the finished product.

This can be done in various forms, such as tablets, capsules, or powders.

The packaging typically includes information such as the product name, ingredients, and dosage instructions.

In conclusion, the production process of tocopherol nicotinate involves several steps, including the isolation of tocopherols, mixing with nicotinic acid, esterification, purification, and packaging.

Each of these steps must be carefully controlled to ensure that the final product is of high quality and meets all relevant safety and efficacy standards.