-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

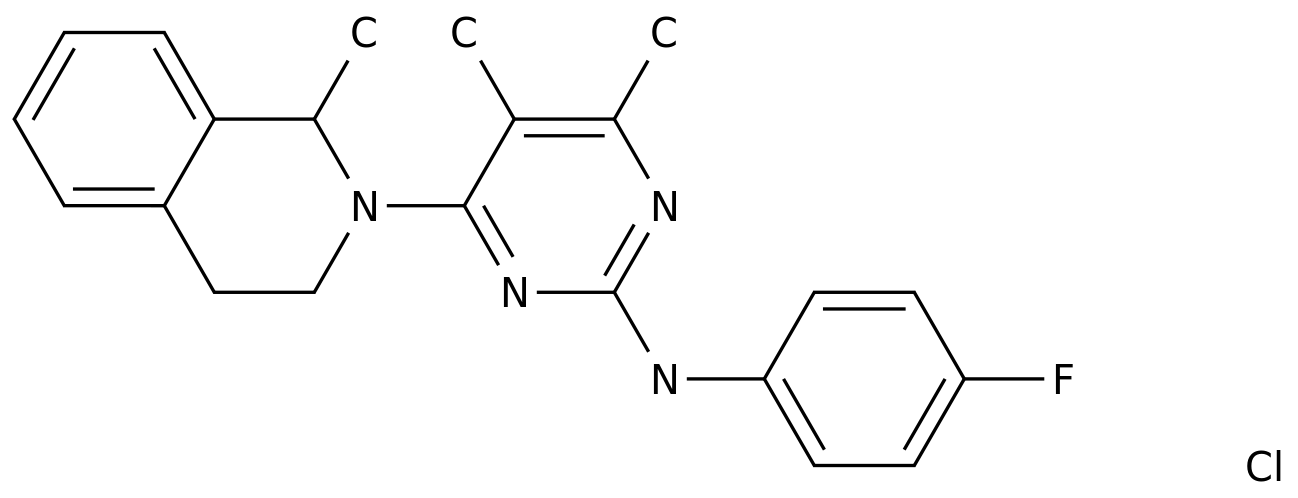

Tizanidine is a benzamide derivative that is used as a muscle relaxant and anti-spasmodic agent.

In the chemical industry, the production process of tizanidine involves several steps, which are discussed in detail below.

Step 1: Synthesis of 2-chlorobenzoic acid

The synthesis of 2-chlorobenzoic acid is the first step in the production of tizanidine.

2-chlorobenzoic acid is synthesized by treating benzoic acid with chloroform and hydrogen chloride in the presence of a catalyst, such as zinc chloride.

The reaction takes place in several stages, including the formation of a carbocation intermediate, which is then protonated by the catalyst to form the final product.

Step 2: Synthesis of 2-chloro-5-nitrobenzene

2-chlorobenzoic acid is then treated with nitric acid to form 2-chloro-5-nitrobenzene.

The reaction is exothermic and requires careful monitoring to avoid excessive heating.

The reaction is carried out in a mixture of water and nitric acid, with the use of a solvent, such as ether, to extract the nitrobenzene product.

Step 3: Synthesis of 2-chloro-6-hydroxybenzothiazole

2-chloro-5-nitrobenzene is then treated with sodium hydroxide to form 2-chloro-6-hydroxybenzothiazole.

The reaction is carried out in a water bath at a controlled temperature to avoid unwanted side reactions.

The reaction produces a yellow precipitate, which is collected by filtration and washed with water to remove impurities.

Step 4: Synthesis of tizanidine

2-chloro-6-hydroxybenzothiazole is treated with formaldehyde and hydrochloric acid to form tizanidine.

The reaction is carried out in a mixture of water and acetic acid, with the use of a solvent, such as ether, to extract the tizanidine product.

The extracted product is then purified by recrystallization to remove impurities.

Quality Control and Purification

During the production process, it is important to monitor the quality of the product at every stage to ensure that it meets the required standards.

This can be done by using various test methods, such as spectroscopy and chromatography.

Additionally, purification is an essential step in the production process to remove any impurities that may have been introduced during synthesis.

The final product is typically purified by recrystallization, which involves dissolving the product in a solvent, allowing it to crystallize out, and then collecting the crystals by filtration.

Conclusion

The production process of tizanidine involves several steps, which require careful monitoring and control to ensure that the final product meets the required standards.

The process begins with the synthesis of 2-chlorobenzoic acid, followed by the synthesis of 2-chloro-5-nitrobenzene, 2-chloro-6-hydroxybenzothiazole, and finally tizanidine.

The production process also involves quality control and purification steps to ensure that the final product is of the required quality and purity.