-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

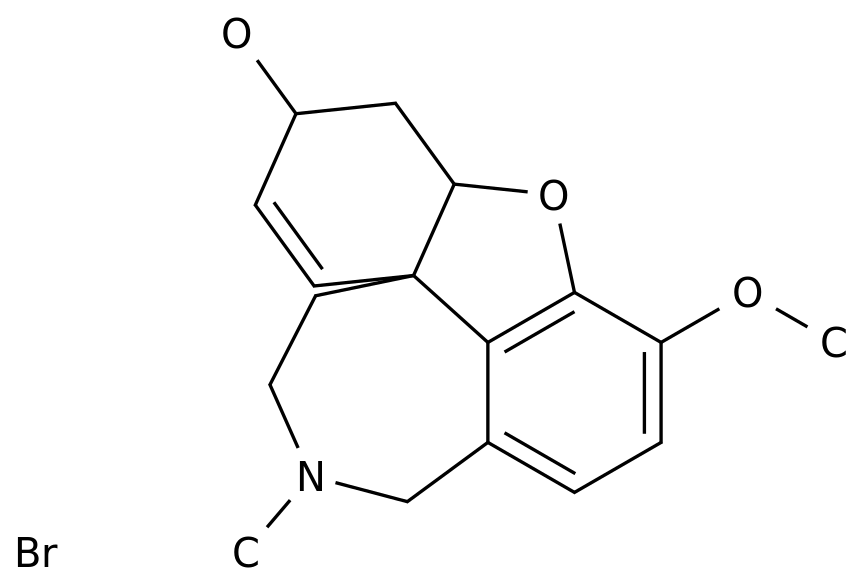

The Production Process of (-)-Securinine in the Chemical Industry

Securinine is a naturally occurring alkaloid that has a wide range of applications in the pharmaceutical and agricultural industries.

It is an important raw material for the production of various drugs and pesticides and is also used in the treatment of various diseases.

In the chemical industry, securinine is produced through a series of chemical reactions that involve several steps and require specialized equipment and conditions.

The production process of securinine can be divided into several stages, including extraction, isolation, purification, and synthesis.

Each of these stages requires careful attention to detail and the use of specialized equipment and techniques.

Extraction

The extraction stage involves the isolation of securinine from its natural source, such as the plant or animal from which it is derived.

This is typically done through the use of solvents, such as water or ethanol, which are used to extract the alkaloid from the plant material.

The extracted material is then filtered to remove any impurities and concentrated to increase the concentration of securinine.

Isolation

The next stage in the production process is the isolation of securinine from other components present in the extracted material.

This is typically done through the use of chromatography, a technique that involves separating the components of a mixture based on their chemical properties.

In the case of securinine, this involves passing the extracted material through a column that contains a stationary phase, such as silica gel or alumina, and eluting the material with a mobile phase, such as a solvent or a mixture of solvents.

Purification

Once the securinine has been isolated, it must be purified to remove any impurities that may have been present in the original extracted material.

This is typically done through the use of various chemical reactions and techniques, such as crystallization, recrystallization, and chromatography.

The purified securinine is then dried and ground into a fine powder, which is ready for use in the next stage of the production process.

Synthesis

The final stage in the production process of securinine is the synthesis of the alkaloid from its component parts.

This involves the use of various