-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

The Production Process of Phenol Red Sodium in the Chemical Industry: An Overview

Phenol red sodium is an important chemical compound used in various industries, including the chemical, pharmaceutical, and textile industries.

It is widely used as an acidity indicator, a catalyst, a flocculant, and a disinfectant.

The production process of phenol red sodium involves several steps, which are carefully designed to ensure the highest quality of the final product.

In this article, we will discuss the production process of phenol red sodium in detail and highlight the key factors that influence its production.

- Raw Material Selection

The production of phenol red sodium begins with the selection of high-quality raw materials.

The raw materials used in the production of phenol red sodium include sodium phenoxide and formaldehyde.

It is essential to use high-quality raw materials to ensure the purity and stability of the final product.

The raw materials are carefully selected and tested to ensure that they meet the required standards.

- Mixing and Reaction

Once the raw materials are selected, they are mixed in specific proportions and subjected to a chemical reaction.

The mixing and reaction process involve the addition of formaldehyde to sodium phenoxide to form phenol red sodium.

The reaction is carefully controlled to ensure that it occurs at the optimal temperature and pressure.

The reaction is also monitored to ensure that it is complete and that no unwanted by-products are formed.

- Separation and Purification

After the reaction is complete, the mixture is separated into its components.

The separated components are further purified to remove any impurities that may be present.

The purification process involves filtering and washing the mixture with water to remove any residual impurities.

The purified mixture is then dried and ready for the next step.

- Crystallization

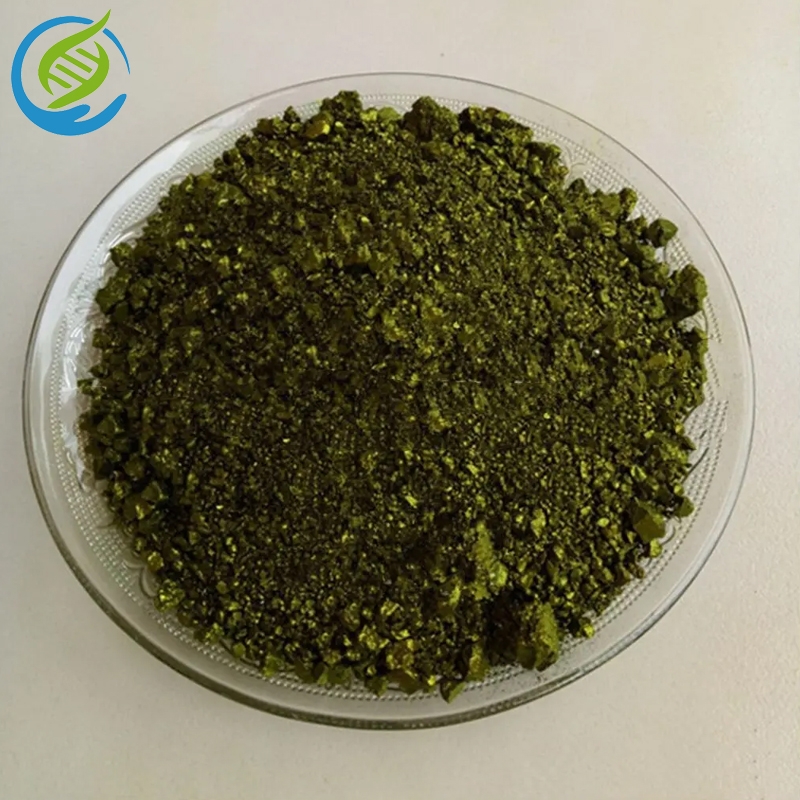

The final step in the production of phenol red sodium is crystallization.

The purified mixture is allowed to cool, and the crystals of phenol red sodium are formed.

The crystals are carefully collected and dried to ensure that they are of the highest quality.

The crystals are then tested for their purity, stability, and other properties to ensure that they meet the required standards.

- Quality Control

Quality control is an essential step in the production of phenol red sodium.

The final product is tested for its purity, stability, and other properties to ensure that it meets the required standards.

The testing process involves various techniques, including spectroscopy, chromatography, and other chemical tests.

The results of the testing are carefully analyzed to ensure that the product is of the highest quality.

- Production Scale

The production scale of phenol red sodium can vary depending on the intended use of the product.

The production process can be scaled up or down to meet the requirements of different industries.

The production scale is carefully designed to ensure that the product is produced efficiently and cost-effectively.

- Economic Factors

The economic factors affecting the production of phenol red sodium include the cost of raw materials, energy cost, and labor cost.

The production process is designed to minimize the cost of production while ensuring the quality of the final product.

The cost of production is also influenced by the scale of production and the intended use of the product.

- Environmental Factors

The environmental factors affecting the production of phenol red sodium include regulations and laws related to waste management, pollution control, and safety.

The production process is designed to comply with all relevant regulations and laws related to environmental safety.

The production process is also designed to minimize the waste generated during the production process.

- Future Developments

The production process of phenol red sodium is constantly evolving to improve efficiency, reduce costs, and meet the changing needs of different industries.

In the future, the production process may involve the use of new technologies, such as