-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

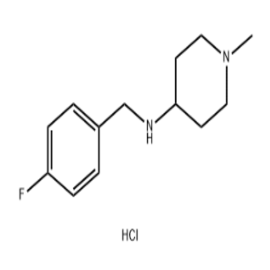

Methyl-thiophen-3-ylmethyl-amine is a chemical compound that is commonly used in various industrial applications.

The production process of this compound involves several steps that must be carried out with precision and care to ensure that the end product is of high quality and meets all relevant safety and regulatory standards.

Step 1: Preparation of Raw Materials

The first step in the production of methyl-thiophen-3-ylmethyl-amine is the preparation of the raw materials required for the process.

This involves the mixing of various chemicals, including thiophenol and methylamine, in appropriate quantities to form the necessary reactants.

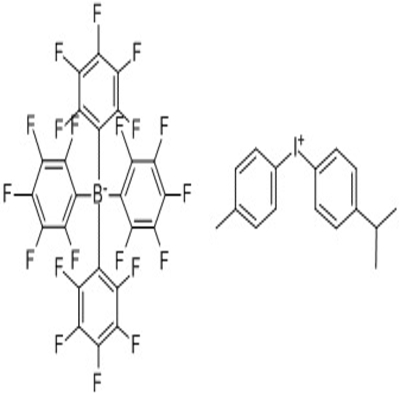

Step 2: Addition of Catalyst

The next step is the addition of a catalyst to the reactants mixture.

The catalyst is a chemical substance that helps to speed up the reaction process without undergoing any chemical changes itself.

The type of catalyst used in the production of methyl-thiophen-3-ylmethyl-amine depends on several factors, including the desired yield, reaction time, and temperature.

Step 3: Heating

After the addition of the catalyst, the reactants mixture is heated to a certain temperature.

This step is crucial because it helps to ensure that the reaction proceeds at an appropriate rate and produces the desired products.

The temperature used in the reaction depends on several factors, including the type of catalyst used, the reactants' concentration, and the desired product yield.

Step 4: Cooling and Neutralization

After the reaction is complete, the mixture is allowed to cool to room temperature.

This step is necessary to prevent any further reactions from occurring.

The mixture is then neutralized using an appropriate neutralizing agent, such as sodium hydroxide or hydrochloric acid, to achieve the desired pH level.

The neutralized mixture is then filtered to remove any solid impurities.

Step 5: Extraction and Purification

The filtrate is then subjected to extraction using an appropriate solvent, such as ethyl acetate or dichloromethane.

This step is necessary to separate the desired product from any other impurities that may be present in the mixture.

The organic layer containing the extracted product is then dried over sodium sulfate and the solvent is removed under reduced pressure to obtain the purified product.

Step 6: Characterization

The final step in the production process is the characterization of the purified product.

This involves the determination of the chemical properties of the product, such as its melting point, boiling point, and chemical composition, using various analytical techniques, such as spectroscopy and chromatography.

The characterization results are used to ensure that the product meets all relevant quality and safety standards.

In conclusion, the production of methyl-thiophen-3-ylmethyl-amine involves several steps that must be carried out with precision and care to ensure that the end product is of high quality and meets all relevant safety and regulatory standards.

The process involves the use of various chemicals and equipment, as well as strict adherence to safety protocols to prevent any accidents or negative environmental impacts.

The product is used in various industrial applications, and its production is a vital component of the chemical industry.