-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

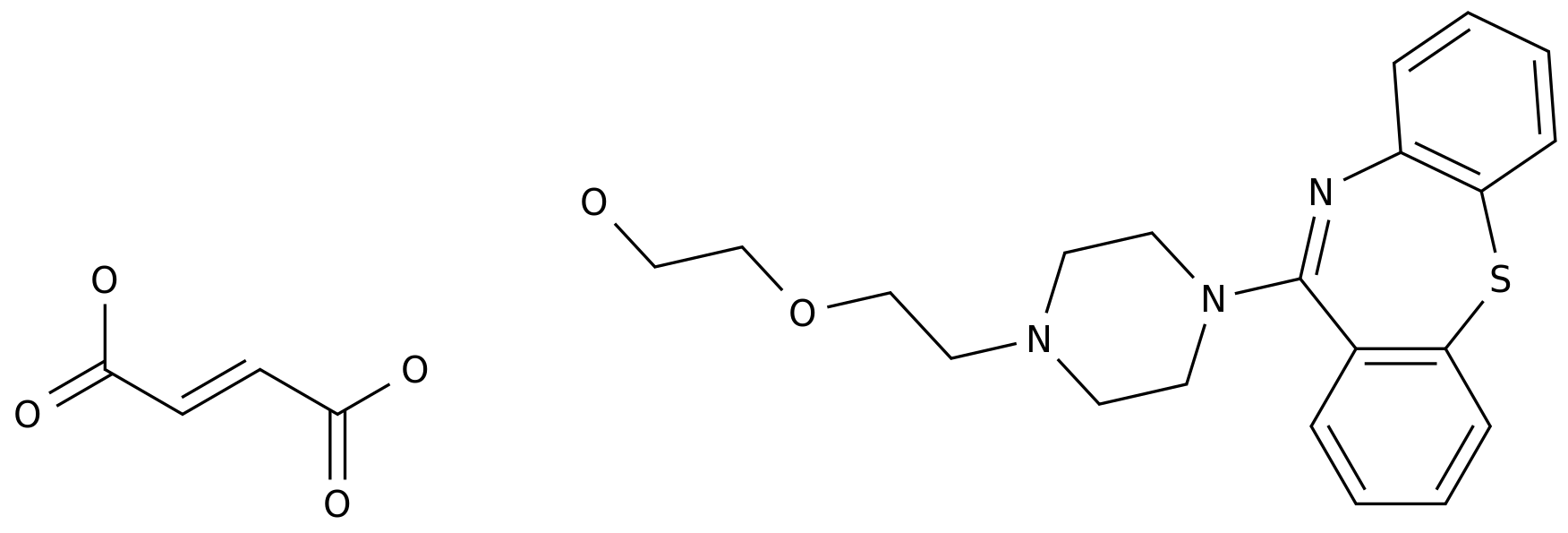

Magnesium valproate, also known as valproic acid, is a pharmaceutical drug that is mainly used to treat epilepsy and bipolar disorder.

The production process of magnesium valproate involves several steps, including the synthesis of the active ingredient, its purification, and its formulation into the final dosage form.

In this article, we will take a closer look at the production process of magnesium valproate, including the chemical reactions involved and the equipment used in each step.

Step 1: Synthesis of Valproic Acid

The synthesis of valproic acid involves several chemical reactions, including the reaction between sodium valproate and 1,2-ethanediol.

The reaction takes place in the presence of a base, such as sodium hydroxide, and is carried out in a batch reactor or a continuous stirred-tank reactor.

The reaction is exothermic, and the heat generated must be removed to maintain the reaction temperature.

The reactants and the solvent used in the reaction must be carefully chosen to ensure the purity of the product.

The solvent used should be anhydrous and should not react with the reactants or the product.

The reaction mixture is then cooled, neutralized, and extracted with a solvent, such as ether or benzene, to separate the product from the reaction mixture.

Step 2: Purification of Valproic Acid

The purified valproic acid is then further purified by chromatography, such as high-performance liquid chromatography (HPLC), to remove any impurities that may have been present in the product.

The sample is then eluted using a suitable solvent, such as water or acetonitrile, and the pure product is collected and dried.

Step 3: Formulation of Magnesium Valproate

The final step in the production process of magnesium valproate is the formulation of the drug into the final dosage form.

The magnesium valproate is mixed with a suitable excipient, such as lactose or starch, and the mixture is then compressed into tablets or filled into capsules.

The dosage form is then coated with a layer of polymer to protect the drug from degradation and to enhance its stability.

Equipment Used in the Production Process

The production process of magnesium valproate requires several pieces of equipment, including reactors, separators, filters, and tableting machines.

Reactors: The reaction between the reactants to form valproic acid takes place in a reactor, which can be a batch reactor or a continuous stirred-tank reactor.

The batch reactor is typically made of stainless steel and has a capacity ranging from 10 to 500 liters.

The continuous stirred-tank reactor is usually made of stainless steel or glass and has a capacity ranging from 1 to 5000 liters.

Separators: The reaction mixture is then separated from the solvent using a separator, such as a centrifuge or a filtration unit.

The centrifuge is typically made of stainless steel and has a capacity ranging from 1 to 5000 liters.

The filtration unit is typically made of stainless steel and has a capacity ranging from 1 to 100 liters.

Filters: The filtrate obtained from the separator is then filtered using a suitable filter, such as a glass fiber filter or a membrane filter.

The filter is typically made of stainless steel or plastic and has a capacity ranging from 1 to 100 liters.

Tableting Machines: The final step in the production process is the formulation of the drug into the final dosage form.

This is typically done using a tableting machine, which can be manual or automated.

The machine is typically made of stainless steel and has a capacity ranging from 1 to 1000 tablets per hour.

Conclusion

The production process of magnesium valproate involves several steps, including the synthesis of the active ingredient, its purification, and its formulation