-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

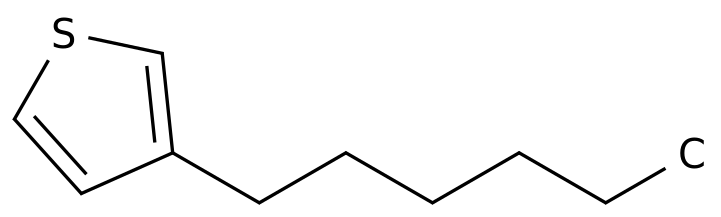

5-Methylbenzo[b]thiophene is an important organic compound that finds widespread use in the chemical industry.

The production process of 5-methylbenzo[b]thiophene involves several steps, each of which requires careful attention to detail to ensure the desired product is obtained.

Step 1: Preparation of Benzaldehyde

The production of 5-methylbenzo[b]thiophene begins with the preparation of benzaldehyde, which is a key intermediate.

This is typically accomplished through the hydrolysis of benzyl chloride using water and sodium hydroxide.

The resulting benzaldehyde is then isolated and purified using standard methods.

Step 2: Nitration of Benzaldehyde

The next step in the production of 5-methylbenzo[b]thiophene is the nitration of benzaldehyde.

This is typically accomplished using a mixture of nitric acid and sulfuric acid.

The reaction is conducted at a temperature of around 80-90°C, with the resulting nitrobenzaldehyde being isolated and purified using standard methods.

Step 3: Reduction of Nitrobenzaldehyde

The next step in the production of 5-methylbenzo[b]thiophene is the reduction of nitrobenzaldehyde to form the corresponding amine.

This is typically accomplished using a reducing agent such as lithium aluminum hydride (LiAlH4).

The resulting amine is then isolated and purified using standard methods.

Step 4: Sulfonation of Amine

The final step in the production of 5-methylbenzo[b]thiophene is the sulfonation of the amine.

This is typically accomplished using a mixture of sulfuric acid and chloroform.

The reaction is conducted at a temperature of around 80-90°C, with the resulting 5-methylbenzo[b]thiophene being isolated and purified using standard methods.

Quality Control

Throughout the production process, it is essential to maintain a high level of quality control to ensure that the final product meets all the necessary specifications.

This involves testing the intermediate compounds for purity and completeness, as well as testing the final product for its chemical properties and stability.

Conclusion

The production process of 5-methylbenzo[b]thiophene involves several steps, each of which requires careful attention to detail.

The key intermediate compounds, such as benzaldehyde and nitrobenzaldehyde, must be prepared and purified using appropriate methods, and the final product must be tested for quality and purity.

By following these steps and maintaining a high level of quality control, it is possible to produce 5-methylbenzo[b]thiophene of the highest possible quality for use in a wide range of chemical applications.