-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

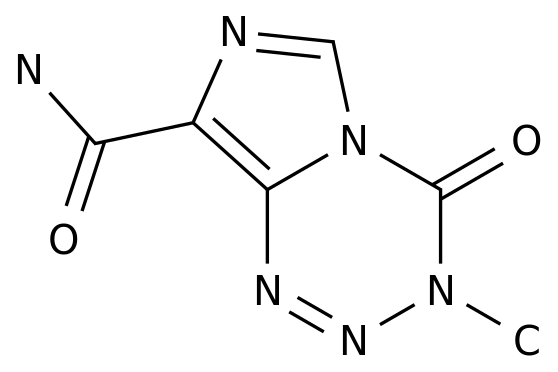

5-(Hydroxymethyl)-alpha,alpha,alpha',alpha'-tetramethyl-1,3-benzenediacetonitrile (HMB) is a high-performance synthetic fiber that is commonly used in the production of clothing and other textile products.

The production process of HMB involves several steps, including the synthesis of the precursor material, the polymerization reaction, and the purification and finishing of the final product.

The synthesis of the precursor material involves the reaction of a phenol and formaldehyde in the presence of a catalyst.

This reaction produces a crude product that is then purified through a series of steps, including extraction, distillation, and filtration.

The next step in the production process is the polymerization reaction, where the purified precursor material is reacted with a diacid chloride in the presence of a catalyst.

This reaction results in the formation of a prepolymer, which is then reacted with a diamine in the presence of a catalyst.

This reaction results in the formation of the desired HMB polymer.

After the polymerization reaction is complete, the final product is purified through a series of steps, including washing, precipitation, and filtering.

The final product is then dried and ground into a powder, which is ready for use in the production of textile products.

In recent years, there has been an increasing demand for HMB due to its excellent mechanical properties, including high strength, stiffness, and toughness.

This has led to an increase in the production of HMB, and as a result, there have been efforts to improve the production process to increase efficiency and reduce costs.

One such effort is the use of microwave irradiation in the polymerization reaction.

Microwave irradiation has been shown to increase the reaction rate and improve the homogeneity of the final product.

This has resulted in a more efficient production process, as well as a higher quality final product.

Another improvement in the production process is the use of solvents that are more environmentally friendly.

Traditionally, the production of HMB has involved the use of organic solvents, such as dimethylformamide and dimethyl sulfoxide.

However, these solvents are not only expensive but also pose a risk to the environment.

Alternative solvents, such as water and aqueous solutions, have been explored as a replacement, and they have been found to be effective while reducing the environmental impact of the production process.

In conclusion, the production process of 5-(Hydroxymethyl)-alpha,alpha,alpha',alpha'-tetramethyl-1,3-benzenediacetonitrile involves several steps, including the synthesis of the precursor material, the polymerization reaction, and the purification and finishing of the final product.

There have been efforts to improve the production process, including the use of microwave irradiation and environmentally friendly solvents, to increase efficiency and reduce costs while maintaining the high quality of the final product.

As demand for HMB continues to increase, it is likely that further improvements will be made to the production process to meet this demand.