-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

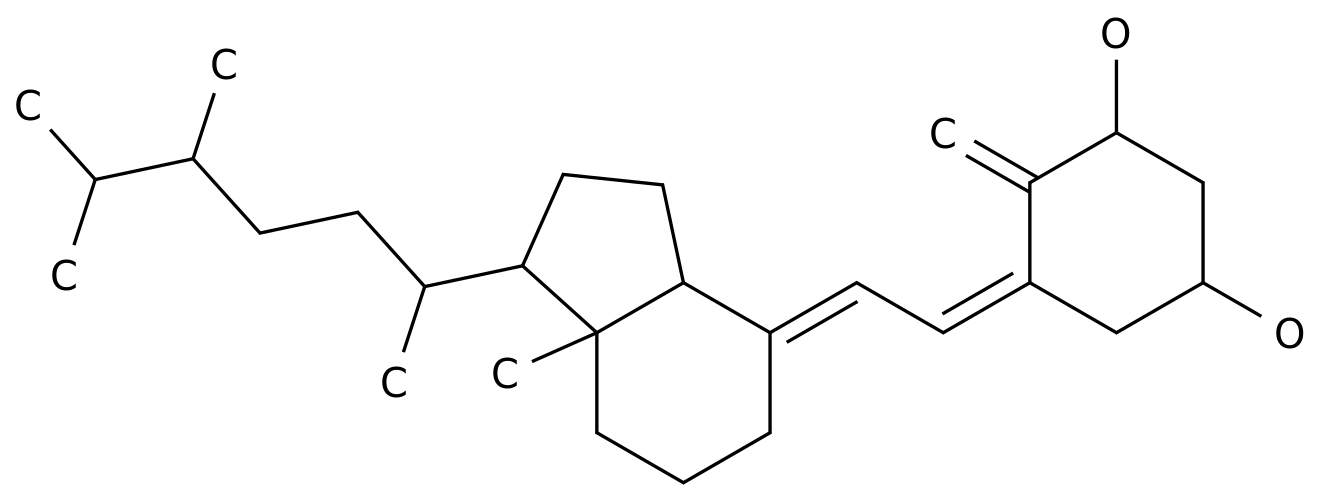

The production process of 1196107-73-9 involves a series of steps that are carefully designed to ensure the purity and quality of the final product.

In the chemical industry, the production process of a compound is a critical factor in determining its effectiveness and safety.

Step 1: Synthesis of the Starting Materials

The production of 1196107-73-9 begins with the synthesis of the starting materials.

These starting materials are carefully selected and are synthesized using a variety of chemical reactions.

The reaction conditions, including temperature, pressure, and the presence of catalysts, are carefully controlled to ensure that the starting materials are synthesized with the desired purity and quality.

Step 2: Purification of the Starting Materials

The starting materials obtained from the synthesis step are purified using a variety of techniques.

These techniques include crystallization, distillation, and chromatography.

Crystallization involves the formation of crystals from the solution or the melt, and the crystals are then separated from the solution using filtration.

Distillation involves the separation of the components of a mixture based on their boiling points.

Chromatography involves the separation of the components of a mixture based on their adsorption properties on a solid support.

Step 3: Synthesis of 1196107-73-9

Once the starting materials are purified, they are ready for the synthesis of 1196107-73-9.

This step involves the use of a variety of chemical reactions, such as condensation reactions, hydrolysis reactions, and polymerization reactions.

The reaction conditions and the selection of the reagents are carefully controlled to ensure that the desired product is synthesized with the desired purity and quality.

Step 4: Purification of 1196107-73-9

After the synthesis step, the product is purified using a variety of techniques, such as crystallization, distillation, and chromatography.

These techniques are used to remove any impurities that may have been introduced during the synthesis process.

The purified product is then dried and sieved to remove any remaining impurities.

Step 5: Characterization of 1196107-73-9

The final step in the production process of 1196107-73-9 is the characterization of the product.

This involves the determination of the physical and chemical properties of the product.

These properties include the melting point, boiling point, density, solubility, and stability of the product.

The characterization step is critical in ensuring that the final product meets the required specifications and is safe for use.

In conclusion, the production process of 1196107-73-9 involves a series of steps that are carefully designed to ensure the purity and quality of the final product.

The steps include the synthesis of the starting materials, purification of the starting materials, synthesis of 1196107-73-9, purification of 1196107-73-9, and characterization of 1196107-73-9.

Each step must be carried out with precision and care to ensure that the final product meets the required specifications and is safe for use in the chemical industry.