-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Introduction:

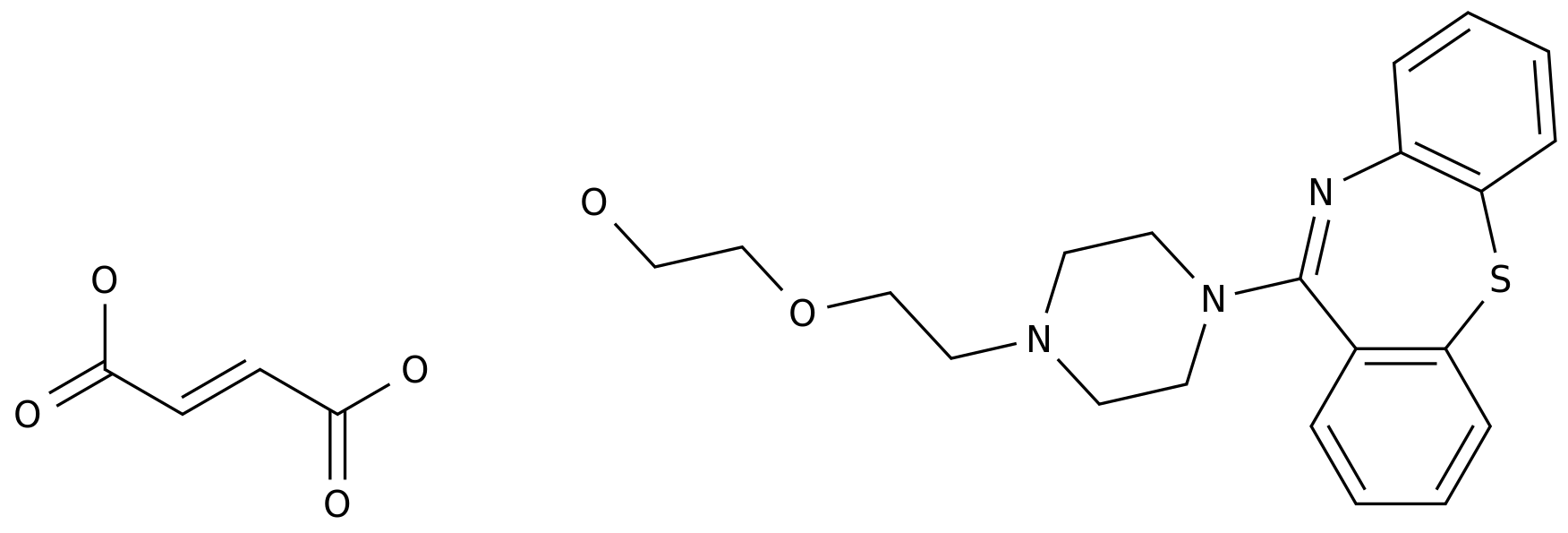

Citalopram hydrobromide is an antidepressant drug that is widely used in the treatment of depression and anxiety disorders.

It is a selective serotonin reuptake inhibitor (SSRI) that works by increasing the levels of serotonin in the brain.

In this article, we will discuss the instructions for using citalopram hydrobromide in the chemical industry.

Process Description:

The production of citalopram hydrobromide involves several steps, including the synthesis of the active ingredient, purification, and formulation.

The following is a general overview of the process:

- Synthesis of the active ingredient:

The synthesis of citalopram hydrobromide involves a series of chemical reactions that convert the starting materials into the final product.

The reaction sequence typically involves the protection of functional groups, deprotection, and condensation reactions. - Purification:

After the synthesis of the active ingredient, it is typically purified to remove any impurities that may have been introduced during the synthesis process.

This may involve techniques such as crystallization, filtration, and chromatography. - Formulation:

Once the purified Active Pharmaceutical Ingredient (API) has been produced, it is typically formulated into a dosage form that can be administered to patients.

This may involve the addition of excipients, such as fillers and binders, as well as the formation of the final dosage form, such as tablets or capsules.

Safety Precautions:

During the production of citalopram hydrobromide, it is essential to follow safety precautions to protect the health of the workers involved in the process and the environment.

Some of the safety precautions that should be followed include:

- Personal protective equipment (PPE):

Workers involved in the production of citalopram hydrobromide should wear appropriate PPE, such as gloves, safety glasses, and lab coats, to protect themselves from exposure to the chemicals and drugs involved in the process. - Storage and disposal:

Chemicals and drugs involved in the production of citalopram hydrobromide should be stored and disposed of in compliance with relevant regulations and guidelines.

This may involve the use of appropriate storage containers and disposal methods, such as incineration or chemical neutralization.

Environmental Considerations:

During the production of citalopram hydrobromide, it is important to consider the potential impact on the environment.

Some of the environmental considerations that should be taken into account include:

- Waste management:

The production process typically generates waste materials, such as chemicals and drugs that must be disposed of in compliance with relevant regulations and guidelines. - Emissions:

The production process may involve the release of emissions into the air, water, or soil.

These emissions should be minimized and controlled to the extent possible to reduce their impact on the environment.

Conclusion:

Citalopram hydrobromide is an important drug in the treatment of depression and anxiety disorders.

Its production involves several steps, including synthesis, purification, and formulation.

It is essential to follow safety precautions and environmental considerations to protect the health of workers and the environment during the production process.

By following these guidelines, the chemical industry can ensure the safe and effective production of citalopram hydrobromide for the benefit of patients.