-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Wen/Zeng calendar 1,2, Liu Liang 1,2, Peng Haomin 1,2, Li Xiaoqiang 1,2, Pan From Yi 1,2, Yang Ruilong 1,2

1 China Electrical Science Research Institute Co., Ltd.; 2 Guangzhou Dynasky Materials Technology Co., Ltd.

Abstract: By analyzing the factors affecting the thermal transfer performance of polyester resins of different structures, the effect of resin acid value on thermal transfer performance was studied, and the effect of some monomers on the thermal transfer performance of polyester resins was studied. The effect of curing promoter on the curing behavior of powder coating is studied by DSC thermal analysis, and the results show that selecting the appropriate curing promoter is very important to improve the coating transfer performance.

0 Foreword

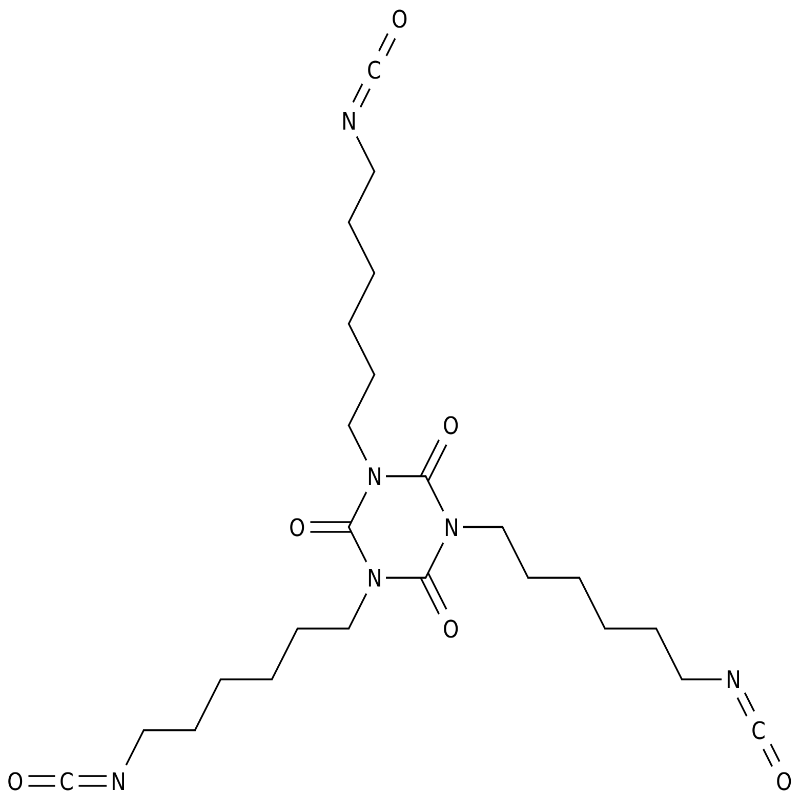

With the development of science and technology, a variety of new technologies and new materials continue to emerge, in these new technologies and materials, thermal transfer technology and thermal transfer powder coatings gradually by the market attention, especially in the home building materials decoration industry, with the overexploitation of natural wood and stone in recent years, leading to a sharp increase in the difficulty of human access to natural decorative materials, driving the home building materials industry to find alternative decorative materials . Aluminum profiles because of its light weight, good durability, easy processing, easy recycling and suitable price and many other advantages, gradually replaced wood and stone applications in the field of home building materials, while the appearance of film transfer technology to solve the aluminum profile decoration effect of a single problem, so that its surface close to natural wood and stone decorative effect, the emergence of this technology has greatly promoted the emergence of aluminum profiles in the home building materials market boom. Powder coating has the characteristics of high efficiency, saving resources, environmental protection and excellent comprehensive performance, compared with the traditional solvent-based coating advantages are obvious, the current aluminum profile coating is mainly powder coating, so the emergence of transfer technology for aluminum profile powder coating performance has put forward new requirements. Due to its good touch and excellent transfer performance, thermal transfer powder coating is mainly polyurethane powder coating, but because the price is too high, the product is difficult to promote the application in the middle and low end of the field. Polyester powder coating prices compared to polyurethane powder coatings are much lower and excellent comprehensive performance, is gradually being concerned by the industry, through early technical exploration, the current TGIC cured thermal transfer polyester resin research more, the market also has corresponding products, and for polyester / epoxy system for thermal transfer powder coating mixed polyester research reports are less.

This paper mainly studies the synthesis of polyester resins used in household thermal transfer polyester/epoxy powder coatings, and analyzes the effect of polyester resin structure on the thermal transfer performance of powder coatings from the perspective of polyester resin synthesis, providing corresponding technical support for the preparation of a hybrid polyester for internal thermal transfer powder coatings suitable for polyester/epoxy systems.

1 Experimental part

1.1 Main raw materials and equipment

PTA): Zhuhai BP Chemical Co., Ltd.; hexydiacid (ADA): BASF; NPG): Jihua BASF Co., Ltd.; ethylene glycol (EG), glycol (DG): Far East Petrochemicals (Yangzhou) Co., Ltd.; Pasto; TMA: Jiangsu Zhengdan Chemical Industry Co., Ltd.; Tin monoclone oxide: Acoma; E-12 epoxy resin; Yueyang Balling Petrochemical Chemical Company; Redstone titanium dioxide: Dongjia, Shandong Province; Sulfate: Guizhou Hongkai; Iron oxide red: Langfang Lilian pigment; GLP588, Sabbath, lightener: South China Sea Chemistry. The above raw materials are industrial grade.

15L reactor: self-assembly; cone viscosity meter: D3MS3LT, UK REL; differential scan heater: DSC1, Mettler-Tolido; electrostature gun: BA-28 type, South China Sea big step spray molding plant; double screw extruder: SLJ-30AF, Yantai Donghui; thermal transfer equipment hot painting machine: XY-001A, Guangzhou Xinyi Machinery Factory.

1.2 polyester resin preparation

50mol polyols (NPG, EG, DG, TMP), 46.3mol polyic acids (PTA, ADA) and 1 0g esterification catalyst, nitrogen gradually heated to esterified water began to generate and distillate, esterification water process should prevent running alcohol, continue to heat up to 245 degrees C after insulation, to be clear and transparent after the reaction system sampling acid value, acid value (Av1) At 20 to 24 mg KOH/g, cool down to 225 degrees C vacuum shrink 1h, acid value (Av2) reaches 7 to 13 mg KOH/g, continue to cool down to 210 degrees C, add 3.8 to 8 6.8mol end agent TMA for end reaction 0.5 to 1h, acid value (Av3) reached 30 to 75 mg KOH/g, continue to cool down to add additives stirring after a period of time out of the material, get polyester resin.

1.3 Preparation of powder coatings and coated film models

weighing the parts according to table 1 formula, premixed, melted extruded, cooled flakes, crushed and crushed after screening to obtain the required powder coating samples. The prepared powder coating is applied electrostature to a pre-treated cold-rolled steel plate and a coating model is obtained by curing 10min at 200 degrees C.

1.4 Analysis and Testing

1.4.1 Polyester Acid Test

The acid value of polyester resins is tested by GB/T6743-2008.

1.4.2 polyester viscosity test

the melt viscosity of polyester resins by ASTMD4287-2000 (2005).

1.4.3 glassed temperature test

the glassed temperature of polyester resin tested at GB/T19466.2-2004 at a warming rate of 10 degrees C/min.

1.4.4 thermal transfer performance test

in accordance with the industry's usual test methods, the transfer paper spread on a cured coating after heat transfer machine heat transfer (185 degrees C/5min) after removal, room temperature cooling 30min after tearing paper, observe the performance of torn paper, transfer pattern and oil printing residue.

1.4.5 Thermoset Behavior (DSC) Test

In the nitrogen atmosphere, the powder coating is analyzed by METLER DSC-1 differential scanning thermometer, with a heating rate of 10 degrees C/min.

1.4.6 curing degree test

take a certain quality curing coating film, put the coating film into a tivon furan solvent at 60 degrees C at 5h, and then 60 degrees C constant temperature drying 24h after the coating film quality, measure the mass residual rate of the coating film, the higher the mass residual rate indicates the higher the curing degree of the coating film.

2 Results and discussion of the effect of

2.1 polyester value on powder coating transfer performance

In the synthesis of polyester resins used in powder coatings, acid values are used to express the number of active groups in polyester that can participate in curing reactions, the amount of curing agent required for the curing of polyester resins with different acid values is also different, and the cross-linking structure of curing substances is also different, and the effect on coating transfer performance is also different. In polyester/epoxy powder coating system, according to polyester acid value and corresponding E-12 epoxy resin dosing can be divided into 70:30, 60:40 and 50:50 a total of 3 curing ratio. In order to investigate the effect of polyester resins of different acid values on the transfer performance of powder coatings, this study synthesized polyester resins with different acid values by adjusting the amount of parabens (sealing agents) in the same formula monomer, Av1 and Av2, and controlled the proportion of pigments and additives in powder coating formulations to be consistent, and the specific formulations of powders were found in Formula 1, Formula 2 and Formula 3, respectively, and the results were compared to Table 2.

from the results of Tables 2 and 1, the higher the acid value of the resin, the easier it is to coat the thermal transfer and tear paper. Analysis of thermal transfer performance factors can be known, the coating transfer effect and the cross-link density of the coating is closely related, it is generally believed that the higher the cross-link density of the coating, the better the performance of the coating after transfer. In the synthesis of mixed polyester resin, TMA is generally involved as a sealing agent in the polyester resin end reaction, the amount of which will determine the final acid value of polyester resin, the more TMA dosage, the higher the acid value of polyester resin. In the polyester/epoxy curing system, because E-12 epoxy resin is a double-lying polymer, in order to obtain the curing of the body structure, the corresponding polyester resin needs to contain a certain proportion of the official energy≥3 monomer structure, it can be learned that TMA essentially plays the role of crosslinking, the more TMA dosing, which means that the higher the crosslink density of the curing system, the better the effect of the transfer of the coating tear paper, because excessive TMA will acidify the main chain structure of polyester, affecting the mechanical properties of the coating and salt spray resistance, its dosing is not the more the better. Therefore, in order to obtain better transfer performance and take into account other properties, the follow-up experiments selected 50/50 mixed polyester resin as the research object.

2.2 Effect of monomers on powder coating transfer in polyester synthesis

For mixed polyester resins, which are mainly used in the field of in-house coating and have low weather resistance requirements, in polyester synthesis formulations, in addition to commonly used NPG, PTA and TMA, other monomers, such as EG, DG, TMP and ADA, these monomers can not only enrich the performance of polyester, but also adjust the cost of polyester formulations.

2.2.1 ethylene glycol has a significant impact on polyester and

. EG is a common fatty family binary alcohol, because of its relatively simple structure and high activity widely used in the polyester synthesis industry, this study in polyester synthesis using EG and other substances in the amount of alternative part of NPG, to investigate its impact on polyester resin transfer performance. The powder formula is Formula 4 in Table 1, and the test results are shown in Tables 3 and 2.

From Table 3 and Figure 2, it can be known that under the premise of controlling the final acid value of polyester, the addition of EG has little effect on the performance of the coating thermal transfer tear paper, nor does it significantly affect the melting viscosity of polyester and the glassification transition temperature (Tg), even if the EG replaces 50% NPG, the molten viscosity of the resin and Tg are not much different. Since both EG and NPG are two-member group monosomes, the addition of EG does not affect the final curing crosslink density of the coating, so it has little effect on the transfer performance of the coating. EG costs are relatively low compared to NPG and the price is more stable, so in the synthesis of mixed polyester, in order to control and stabilize the formulation cost of polyester, the appropriate amount of EG is usually added to the formulation. Although the addition of EG has little effect on the properties of the resin, but its dosing is not the more the better, in subsequent experiments found that due to differences in surface pressure, excessive EG in the polyester structure will cause a decrease in the anti-jamming capacity of powder coating, specifically manifested in the coating surface will shrink hole phenomenon, seriously affecting the appearance of the coating, so its addition should not exceed 30%.

effects of 2.2.2 glycol on polyester and its transfer

. DG is a monomer composed of 2 EG dehydration, its chain segment is longer than EG and the structure contains ether bonds, is a more flexible monomer, in the synthesis of mixed polyester resin, usually used to regulate the Tg and molten viscosity of polyester, At the same time can also improve the flexibility and appearance flatness of the coating, this study in polyester synthesis using DG and other substances to replace part of NPG, to investigate its effect on the transfer performance of polyester resin, powder formula for Table 1 formula 4, test results can be seen in Table 4 and Figure 3.

As can be known from Tables 4 and 3, the addition of DG in the formulation has little effect on the transfer performance of the coating, but the Tg and viscosity of the resin show a clear downward trend, when the DG dosing is 30%, the melting viscosity of the resin decreased from 4660mPa.s to 2380mPa.s, Tg from 67.6 The reason for this phenomenon is that the introduction of DG changes the main chain structure of polyester, comparing the molecular structure of NPG and DG, it can be found that DG is a monomer with a long chain flexible structure, the introduction of the monomer structure in the main polyester chain, which is conducive to increasing the activity of the molecular chain segment, thereby reducing the Tg of resin. The melting viscosity of polyester resin is also related to the main chain structure, the effect of fat family binary alcohol with side chain or asymmetric structure on the resin melt viscosity is greater than that of straight chain fat family binary alcohol; Under the condition that the curing is sufficient, the addition of DG does not affect the final curing degree and cross-link density of the coating, so it has little effect on the transfer performance of the coating. Although the addition of DG has little effect on the transfer performance of the coating, in practice, due to the low Tg polyester and its preparation of powder coatings in storage prone to the phenomenon of clustering, to the subsequent construction brought great inconvenience, in order to meet the storage stability requirements, polyester formulation DG dosage should not exceed 20%.

effects of 2.2.3 hedic acid on polyester and its transfer

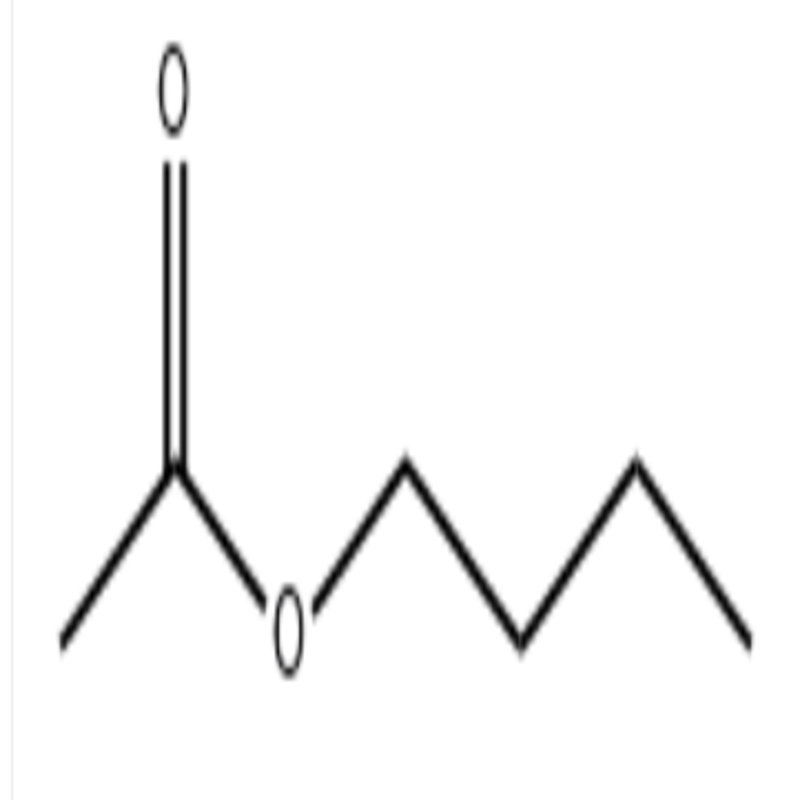

. ADA is a long straight-chain fat family binary acid containing 6 carbon atoms, because its molecules contain a strong flexible structure, can improve the flexibility of the resin main chain. In the synthesis of polyester used in powder coatings, in order to improve the appearance leveling and mechanical properties of the coating, a certain amount of ADA replacement part of the aromatic multi-acid is usually added. In this study, the use of ADA and other materials in polyester synthesis to replace part of PTA, to investigate its effect on the transfer performance of polyester resin, powder formulation for Table 1 formula 4, the results can be seen in Table 5 and Figure 4.

as can be found from Tables 5 and 4, with the increase in ADA additions in the formulation, the Tg and molten viscosity of polyester resins showed a linear decrease, the appearance of the coating film leveled, and the tearing paper performance was not very different. As mentioned in the previous section, the addition of flexible monosomes is conducive to the rotation of the main chain, increasing the movement of the chain segment, thereby reducing the Tg and molten viscosity of the resin. Compared with the molecular structure of DG, ADA has a longer flexible chain segment, which has a more obvious effect on the Tg and melt viscosity of the resin, especially in the condition of replacing the aromatic binary acid of rigid structure, the degree of decline is much higher than the DG of the adipose family to replace the NPG of the fat family, so when a smaller amount of ADA is introduced in the formula, the resin Tg and molten viscosity are significantly reduced. Since polyester powder coatings are slowly melting flat while curing, resins with low melt viscosity facilitate the melting flow of powder coatings and the coating looks better. Both ADA and PTA are two-function group monosomes, and the ADA replacement part of PTA does not affect the final curing crosslink density of the coating, so it has little effect on the transfer performance of the coating. In order to balance the appearance of the coating with the storage stability of the powder coating, ADA.