Study on the extraction process of chlorogenic acid

-

Last Update: 2014-02-21

-

Source: Internet

-

Author: User

Search more information of high quality chemicals, good prices and reliable suppliers, visit

www.echemi.com

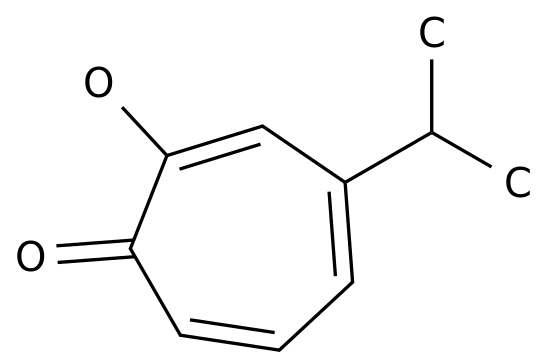

Chlorogenic acid (3-0-caffeoylquinic acid) Acid) is widely distributed in the plants of Lonicerae, Rosaceae, Compositae, Rubiaceae and Eucommiaceae It is the main effective component of eucommia, honeysuckle and other traditional Chinese medicine for clearing heat, detoxifying, anti-inflammatory and antibacterial Water extraction or water alcohol extraction process has a great influence on the content of chlorogenic acid due to the different time and temperature of extraction and concentration : V-N '[* Z8 x $a & Q "t honeysuckle extraction process [Shandong Institute of biological medicine] literature data: Honeysuckle 10 + 8 times pure water extraction for 1 H + 1 h and then concentrated to 1 / 3 times honeysuckle amount 50 ℃ decompression concentration and drying L2 E; U4 D3 n extraction solvent research: water extraction: water extraction alcohol precipitation: 50% alcohol extraction yield =1.11 (60.6%): 0.95 (51.7%): 1.02 (55.5%); & I2 C* \6 X "H3 O;", "water and water extraction time:":::: (51.7%): 1.11 (54.7%): 0.96 (47.3%); drying method investigation: 47.3% vacuum decompression: spray: at atmospheric temperature, "atmospheric pressure" 3 H7 U (M% d + C "d-f honeysuckle chlorogenic acid extraction process [School of medicine, Anhui Medical University] literature data: the gold and silver pollen was sifted through 50 mesh, the amount of water was 30 times, decocting for 3 times, each time for 30 minutes, the total extract yield was 60.74%, and the content of chlorogenic acid was 6.78% The experimental results were ideal, which showed that the process conditions were simple, stable and feasible Extraction and separation of chlorogenic acid and isochlorogenic acid from Flos Lonicerae [source unknown] literature data: Flos Lonicerae LKG crushed with 15 times 95% ethanol, filtered by reflux for 1h, residue added with 10 times 95% ethanol, reflux for 30min, repeated extraction of the filtered residue once, combined with cold filtration of the filtrate, the filtrate was decompressed to recover ethiol to a volume of about 1000ml, added with 30% lead acetate to no longer produce precipitate, and the precipitate was obtained by filtration with 95% ethanol Measure and grind the slurry, add 10% sulfuric acid to adjust pH = 3, filter it, wash the residue with appropriate alcohol for 5 times repeatedly, combine the ethanol solution, add 10% sodium hydroxide to adjust pH = 6, filter it, reduce pressure and recover it to a small volume, add about 2 times of distilled water to dissolve it, add 1 mol hydrochloric acid to adjust pH = 2, extract it repeatedly with ethyl acetate, add 2% active carbon to the extraction solution, water-soluble reflux 30 Min, cool and filter, recover ethyl acetate to a small volume, add chloroform until no precipitate is produced, filter, and obtain light yellow precipitate The precipitate was dissolved with anhydrous ethanol, the sample was mixed with silica gel, and separated by dry column method About 15 cm was expanded on ethyl acetate: formic acid: water = 10:1:0.2, and inspected under UV light Chlorogenic acid and isochlorogenic acid were collected respectively Chlorogenic acid and isochlorogenic acid were obtained by methanol elution, and then separated by dry column again to obtain pure chlorogenic acid and isochlorogenic acid *Z: [4 U -? 9 P8 u] isolation and purification of chlorogenic acid from honeysuckle [source unknown] literature data: | / y, O, C R6 E was purified by lipophilic adsorption chromatography and Sephadex gel chromatography The water extract was pre separated by lipophilic adsorption resin column chromatography 0.1mol/L-1 hydrochloric acid adjusted pH to about 4 Dextran gel sephadexLH-20 was refined and purified, and the elution solvent was 50% acetone aqueous solution The purity of chlorogenic acid obtained from the product was >98% The optimal separation conditions are: pH 4, eluent 50% acetone solution and flow rate 0.5ml/min The chlorogenic acid in Flos Lonicerae was extracted by LH-20 The extraction process of chlorogenic acid in Flos Lonicerae was studied [Guangxi Light Industry School] document data: weigh 20 g Flos Lonicerae, add 160 ml of 45% ethanol, soak pH = 4 in a constant temperature bath for 3 h twice at 45 ℃, filter while hot, add 5% NaOH solution into the filtrate, adjust pH = 7, and separate the solution through D101 macroporous adsorption resin column Remove impurities, elute with water, combine the solution, concentrate and dry under reduced pressure, dry at 70 ℃ at constant temperature, grind into powder shape, seal up and then obtain 6% content of the finished product Study on the extraction of chlorogenic acid from Eucommia ulmoides leaves: both leaves and bark contain chlorogenic acid Among them, the content of leaves is relatively high, generally around 5% The leaves of air dried Eucommia ulmoides Oliv are crushed into fine powder, degreased and pigmented first, then extracted with 95% ethanol The ethanol extract is concentrated into extract under reduced pressure After mixing with clean fine sand, it is extracted with hot water for several times, so that chlorogenic acid is converted into water, and the residue is discarded The aqueous solution is extracted with ether, and the fat soluble impurities are further removed The saturated inorganic salt solution is added to the degreased aqueous solution, Until the precipitation is complete and slightly excessive At this time, the chlorogenic acid in water combines with metal ions to form insoluble salt After the precipitation is separated by centrifugation and the metal ions in the precipitation are removed, the filtrate is extracted several times with organic solvent, the solvent is recovered, and the crude chlorogenic acid is obtained The purified chlorogenic acid is obtained by fractional crystallization and recrystallization, and the yield is about 0.15%.

This article is an English version of an article which is originally in the Chinese language on echemi.com and is provided for information purposes only.

This website makes no representation or warranty of any kind, either expressed or implied, as to the accuracy, completeness ownership or reliability of

the article or any translations thereof. If you have any concerns or complaints relating to the article, please send an email, providing a detailed

description of the concern or complaint, to

service@echemi.com. A staff member will contact you within 5 working days. Once verified, infringing content

will be removed immediately.