-

Categories

-

Pharmaceutical Intermediates

-

Active Pharmaceutical Ingredients

-

Food Additives

- Industrial Coatings

- Agrochemicals

- Dyes and Pigments

- Surfactant

- Flavors and Fragrances

- Chemical Reagents

- Catalyst and Auxiliary

- Natural Products

- Inorganic Chemistry

-

Organic Chemistry

-

Biochemical Engineering

- Analytical Chemistry

-

Cosmetic Ingredient

- Water Treatment Chemical

-

Pharmaceutical Intermediates

Promotion

ECHEMI Mall

Wholesale

Weekly Price

Exhibition

News

-

Trade Service

Abstract: At present, on the market, there are relatively mature products for high-gloss, sand-textured and low-temperature fast-curing (180℃@5min high-flexibility bending transfer powder coatings, while low-gloss high-flexibility bending powder coatings are still rare in the market.

1.

2.

2.

2.

3.

Results and discussion

3.

1 Extinction Path Selection

In order to make low-gloss powder, the matting problem of pure polyester powder coating needs to be considered

.

Common matting agents include physical matting agents and chemical matting agents.

The chemical matting methods of pure polyester powder are: epoxy acrylic matting resin, shuttle-based acrylic matting resin, and physical matting methods are: dry mixed matting, matting wax, acrylate polymerization thing

.

The comparison of various extinction methods is shown in Table 1

.

It can be seen from Table 1 that the carboxyl acrylic matting resin needs to consume TGIC, the TGIC content in the formula is high, the powder Tg is low, and the storage stability is poor

.

The dry blend matt surface has many bright spots, and the lower the gloss, the more bright spots, affecting the appearance of the coating

.

Matting wax and acrylic polymers are difficult to eliminate to very low gloss

.

Therefore, we choose epoxy acrylic resin, which not only can eliminate low light, but also has high powder Tg and fine coating appearance

.

3.

2 Selection of polyester resin

The acid value, functionality and curing degree of polyester resin will affect the transfer effect

.

Since the surface tension of epoxy acrylic resin is quite different from that of polyester resin, it is necessary to select polyester resin that matches epoxy acrylic resin

.

Table 2 shows the appearance of coatings prepared by combining polyesters with different acid values and viscosities with epoxy acrylic matting resins

.

Polyester A has high acid value, high cross-linking density, and cracks during bending; Polyester B is poorly miscible with the matting curing agent, and the surface is patterned; Polyester D has high viscosity and is difficult to matte; Polyester C has a low acid value, but Epoxy acrylic matting resin improves the crosslinking density and compactness of the coating, does not stick to paper for transfer printing, has good miscibility with matting curing agent, good leveling, fine surface, moderate resin viscosity and easy matting

.

Therefore, it is necessary to select a suitable polyester resin according to the acrylic resin to match it

.

3.

3 Selection of epoxy acrylic matting resin 3.

3.

1 Synthesis of epoxy acrylic matting resin

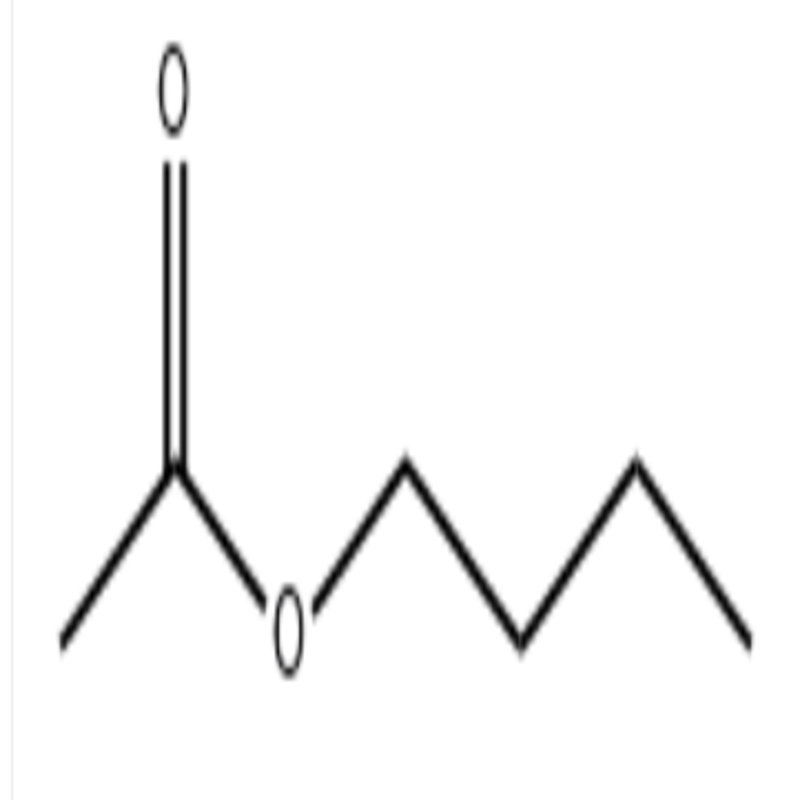

Epoxy acrylic matting resin is prepared by free radical polymerization of styrene, methacrylate, acrylate, glycidyl methacrylate (GMA) and other unsaturated monomers

.

Among them, styrene is used as a hard monomer to increase the Tg of the resin; methacrylate and acrylate are used as soft monomers to improve the flexibility of the coating; glycidyl methacrylate (GMA) is a cross-linking monomer, To provide the epoxy groups that can be cured and cross-linked, the amount of GMA monomer determines the cross-link density of the coating

.

The epoxy acrylic resin synthesis is shown in Figure 1

.

3.

3.

2 Application of Epoxy Acrylic Matting Resin

Epoxy acrylic matting resin is a film-forming substance, and its compatibility with polyester resin directly affects the performance of the coating

.

In this paper, three different epoxy acrylic matting resins are selected and tested with polyester C.

The DSC analysis of the three epoxy acrylic resins is shown in Figure 2, and the properties of the three resins and their coatings are shown in Table 3

.

The difference in surface tension between epoxy acrylic matting resin and polyester resin causes uneven curing and shrinkage of the coating film, resulting in micro-roughness.

Roughness, gloss reduction

.

1# Epoxy acrylic resin has low Tg and low epoxy equivalent weight (EEW), and there are many soft monomers in the resin, so it is difficult to extinct; 2# Epoxy acrylic resin has high Tg and high EEw, and there are many hard monomers in the resin, and the gloss of the coating can be eliminated.

Very low, but the surface fineness of the coating is slightly worse and the hand feel is poor; the Tg of 3# epoxy acrylic resin is between 1# and 2#, which not only has a good matting effect, but also has a good fineness of the coating.

and feel

.

Experiments show that the matting resin has a great influence on the surface of the coating.

The difference in the surface tension of different matting resins and polyester produces different gloss and fineness of the coating

.

3.

4 Influence of aliphatic glycidyl esters

It can be seen from Figure 1 that the epoxy group in epoxy acrylic resin is on the branch chain, unlike ordinary epoxy resin in which the epoxy group is at both ends of the molecular chain.

Therefore, the coating made of epoxy acrylic resin is cross-linked The bonding density is high, and the coating flexibility is poor; in addition, epoxy acrylic resin contains hard monomers such as styrene, which will also affect the coating flexibility

.

,,,

。、4

。

4,,,、

。,/,

。

3.

5

、,,、,,5、6,3、4

。

、,,,,

。

4、

,

。,、,,,

。

。,

。

(l),,

。

(2),,

。

(3) The selection of matting resin is very important.

Too little styrene introduced into the synthetic matting resin makes it difficult to matte; too much styrene will cause patterns on the surface of the coating and poor fineness; the matching of matting resin and polyester resin is also very important.

.

.